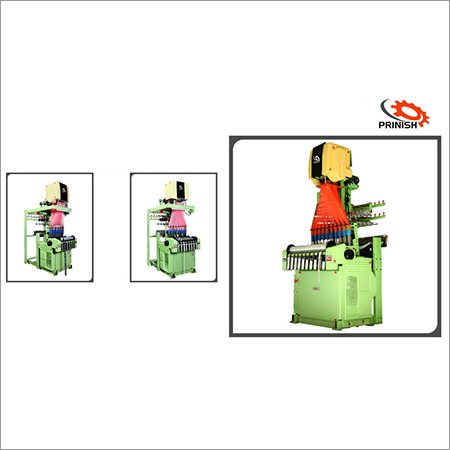

Festooning Machine

Festooning Machine Specification

- Type

- Festooning Machine

- Material

- Mild Steel

- Capacity

- 200-300 kg/hr

- Computerized

- No

- Automatic Grade

- Automatic

- Control System

- PLC Control

- Working Temperature

- 5C 45C

- Power

- 3 kW

- Size

- Standard

- Width

- 400-600 mm

- Weight (kg)

- 750 kg

- Dimension (L*W*H)

- 2200 x 1100 x 1650 mm

Festooning Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 10 Days

About Festooning Machine

Features:

- Easy to maintain

- Easy to use

- High efficiency

- Most affordable

FAQs:

Q: What is a Festooning Machine?

A: Festooning Machine is a type of textile machinery used in the preparation of yarns for the weaving process. It is used to wind yarns onto a beam in an organized and parallel manner, creating a festoon that can be used for weaving.

Q: How does a Festooning Machine work?

A: Festooning Machine works by winding yarns onto a beam in a specific pattern, usually using a creel to hold the yarn cones. The machine may also use various tension devices to ensure proper tension and organization of the yarns during the winding process.

Q: What are the benefits of using a Festooning Machine?

A: The benefits of using a Festooning Machine include increased efficiency, improved yarn organization, and consistent yarn tension. The machine helps to ensure that the festoon is evenly wound, with consistent tension, making it easier to weave and resulting in a more uniform and high-quality final fabric.

Advanced Performance and Versatility

With its variable frequency drive and PLC-based automatic grade control, the Festooning Machine delivers accurate and consistent festooning for various materials. The structure is designed for stability and minimal vibration, making it ideal for industrial environments where long-term reliability and straightforward installation are priorities.

Engineered for Safety and Efficiency

Safety features such as emergency stop switches and comprehensive safety guards provide customer assurance, while the automatic tension control system maintains material integrity throughout operation. Noise-reduction measures keep sound levels below 70 dB, ensuring a safer and more comfortable workspace for operators.

FAQs of Festooning Machine:

Q: How does the Festooning Machine adjust speed and tension during operation?

A: The Festooning Machine utilizes a variable frequency drive (VFD) for precise speed control, allowing operators to adjust the pace as required. Tension is managed automatically or can be set manually, ensuring consistent festooning results for different materials without causing damage.Q: What materials and applications are suitable for this Festooning Machine?

A: This machine is designed to process wires, cables, tapes, and web materials, making it versatile for a range of industrial uses including cable manufacturing, textile production, and related sectors requiring organized, looped material handling.Q: When and where should the Festooning Machine be installed?

A: The machine is intended for floor-mounted installation within facilities that have access to a 380 V, 3-phase power supply. It is suitable for environments with temperatures between 5C and 45C, and should be placed on a flat, rigid surface to maximize stability and operation efficiency.Q: What is the operational process of the Festooning Machine?

A: Materials are fed into the machine, where the PLC control system manages speed and tension. As the material is festooned, it is looped back and forth in precise lengths up to 60 meters, which are then gathered for easy storage or transport.Q: How can users benefit from the machines safety and noise-reduction features?

A: The integration of emergency stop switches, safety guards, and a rigid base frame enhances operational safety. With noise levels kept below 70 dB, the machine contributes to a quieter working environment, reducing fatigue and improving operator comfort.Q: Is any after-sales service provided for the Festooning Machine?

A: Yes, comprehensive after-sales service is available across India, including installation guidance, operation training, periodic maintenance, and technical support to ensure maximum uptime and user satisfaction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Needle Loom & Jacquard Machine Category

Computerrized Narrow Fabric Jacquard Loom

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 4001200 Picks Per Minute

Type : Computerrized Narrow Fabric Jacquard Loom

Size : Customizable (Standard Size Available)

Width : 30mm 700mm

Computerized Jacquard Needle Loom

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : Up to 600 mm weaving width

Type : Computerized Jacquard Needle Loom

Size : Standard/Customizable

Width : 600 mm

Warping Machine

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 1000 meters/hour

Type : Automatic Warping Machine

Size : Large

Width : Up to 2800 mm

Double Needle Loom

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 150200 m/h

Type : Double Needle Loom

Size : Standard Industrial

Width : 400 mm 800 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free