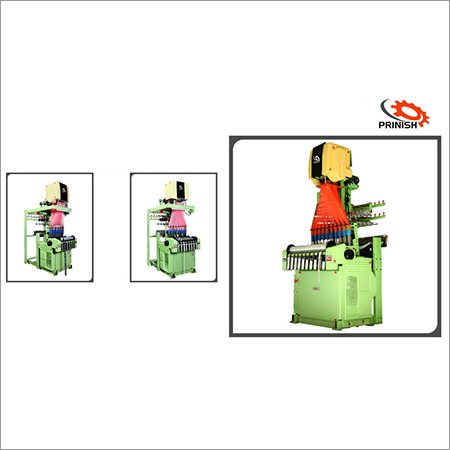

Needle Loom Single Tape

Needle Loom Single Tape Specification

- Type

- Single Tape Needle Loom

- Material

- High-grade Steel and Alloy Components

- Capacity

- Up to 200 meter/hour

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Plate Type

- Chain Plate Type

- Control System

- Mechanical / Manual Lever

- Working Temperature

- Ambient (10C - 40C)

- Power

- 1.5 kW

- Size

- Medium (Standard Industrial)

- Width

- 10 mm to 120 mm (Adjustable)

- Weight (kg)

- Approx. 750 kg

- Dimension (L*W*H)

- 2300 mm x 950 mm x 2100 mm

Needle Loom Single Tape Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 10 Days

About Needle Loom Single Tape

Exceptional Features for Modern Tape & Fabric Production

The Needle Loom Single Tape stands out for its adjustable width (10 mm to 120 mm), robust positive feed system, and chain plate design. Its application media include a range of synthetic and natural fibers suited for narrow fabric manufacturing. The application surface is tailored for industrial environments, ensuring consistent results. Safety attributes like emergency stop and protective shielding guarantee operational security while the automatic lubrication system extends machine longevity.

Efficient Packaging, Supply Capacity & Trusted Certifications

Each loom is packaged with an immaculate outlay to ensure secure transport, arriving on reinforced pallets or customized crates. Dispatching times are rapid thanks to our reliable logistics, and a quick quotation process streamlines procurement. With a robust supply ability to meet bulk orders, our looms arrive with essential quality certificationsensuring compliance, performance assurance, and integrity for importers, exporters, and suppliers across Indias textile sector.

FAQs of Needle Loom Single Tape:

Q: How is the needle configuration determined for this loom?

A: The needle configuration is customizable based on your specific tape and fabric manufacturing requirements, allowing seamless adaptation for various production needs.Q: What safety features does the Needle Loom Single Tape offer?

A: Safety is enhanced with an emergency stop button and protective covers, providing a secure working environment and reducing risks during operation.Q: When can I expect dispatching after placing an order?

A: Dispatching typically occurs promptly after confirmation of your order and quotation acceptance. Specific timelines are communicated during the order process.Q: Where can this loom be installed for optimal operation?

A: This loom is ideal for installation in industrial facilities, textile mills, or manufacturing units, operating optimally in ambient temperatures ranging from 10C to 40C.Q: What is the process for requesting a quotation or outlay details?

A: To receive a detailed quotation or outlay, simply contact our sales team with your specifications. We provide prompt, transparent pricing and supply details.Q: How does the automatic lubrication system benefit usage?

A: The automatic centralized lubrication system reduces maintenance frequency, ensuring smoother operations and extending the mechanical lifespan of the loom.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Needle Loom & Jacquard Machine Category

Computerrized Narrow Fabric Jacquard Loom

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : 7001400 kg

Type : Computerrized Narrow Fabric Jacquard Loom

Material : Highstrength Alloy Steel Frame, Precision Cast Aluminum Components

Control System : Other, PLC Controlled with Touchscreen Interface

Computerized Jacquard Needle Loom

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : Approx. 1800 kg

Type : Computerized Jacquard Needle Loom

Material : Heavyduty Steel, Aluminum Alloys

Control System : Other, PLC Based Control Panel with Touch Screen

Warping Machine

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : 3200 kg

Type : Automatic Warping Machine

Material : Mild Steel

Control System : Other, PLC Controlled

Double Needle Loom

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : 1800 kg

Type : Double Needle Loom

Material : Highquality Steel and Alloy

Control System : Other, PLC Controlled

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free