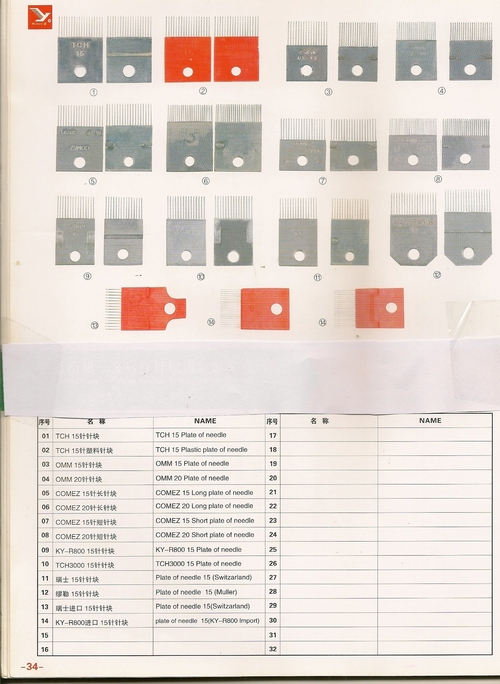

PLASTIC & METAL BLOCK

PLASTIC & METAL BLOCK Specification

- Drive Motor

- None

- Product Type

- Plastic & Metal Block

- Material

- Plastic and Metal

- Type

- Block

- Capacity

- Standard

- Weight (kg)

- Variable (Depends on size)

- Computerized

- No

- Automatic

- No

- Cooling System

- Not Required

- Drive Type

- Manual

- Dimension (L*W*H)

- Varies as per requirement

- Feature

- Corrosion Resistant, Durable, Precise Dimensions, High Strength

- Color

- Multicolor (Typically Blue and Silver/Grey)

- Motor

- None

- Mechanical Precision

- High (for metal inserts)

- Control System

- Manual

PLASTIC & METAL BLOCK Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

About PLASTIC & METAL BLOCK

Versatile Applications & Premium Surface Quality

PLASTIC & METAL BLOCKS are widely used for assembly setups, jigs, fixtures, and mechanical model bases. The smooth and polished surfaces provide a top-tier finish, ensuring minimal friction and reliable performance in engineering applications. They are commonly applied on surfaces requiring durability and stability, such as workbenches, machine beds, and manufacturing fixtures. Their rectangular or cuboid form enhances stability and makes them suitable for multiple mounting or alignment purposes in both industrial and educational settings.

Swift Handover, Global Export Markets, Flexible Payment

Our PLASTIC & METAL BLOCKS are prepared for prompt handover, with delivery times dependent on item specifications and quantity. Export markets include Asia, Europe, Africa, and the Middle East, where our blocks provide unrivaled value in various industries. Payment terms are designed for convenience, supporting bank transfers, letters of credit, and other secure modes to facilitate a smooth process from order to arrival. As a leading exporter, importer, manufacturer, and supplier, we ensure every transaction is completed with efficiency and transparency.

FAQs of PLASTIC & METAL BLOCK:

Q: How are PLASTIC & METAL BLOCKS typically used in mechanical assemblies?

A: They are mainly utilized as bases for jigs, fixtures, and assembly components, offering a stable, corrosion-resistant foundation with precise dimensions suited for high-precision tasks.Q: What surface finish can I expect on these blocks?

A: Each block is produced with a smooth, polished finish, ensuring minimal surface defects and optimized performance for mounting or contact applications.Q: When will my order arrive after purchase?

A: Delivery times vary depending on your region and the specific order requirements, but we always prioritize swift handover and clear communication throughout the shipping process.Q: Where are your main export markets for these blocks?

A: Our main export markets include Asia, Europe, Africa, and the Middle East, serving engineering, manufacturing, and educational institutions globally.Q: What are the main benefits of using these blocks over alternatives?

A: Our blocks offer outstanding corrosion resistance, easy machinability, high tensile strength for metal variants, and precise dimensions, providing value and reliability for various applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crochet & Needle Loom Spare Part Category

Automatic Label Cutting and Endfold Machine

Price Range 50000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Textile label processing equipment

Weight (kg) : Approx. 300 kg

Type : Other, Automatic Label Cutting & Endfold Machine

Color : Other, Industrial grey or custom

Circular Loom Spare Parts

Price Range 50000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Spare Parts

Weight (kg) : Varies by Part Type

Type : Other, Circular Loom Spare Parts

Color : Other, Silver, Grey, as per Part

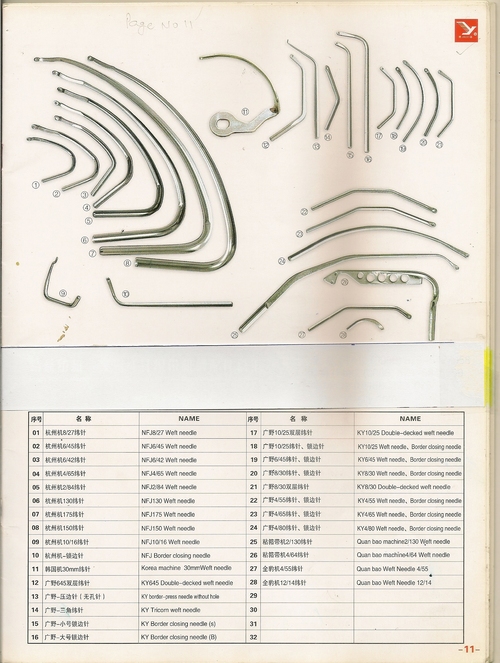

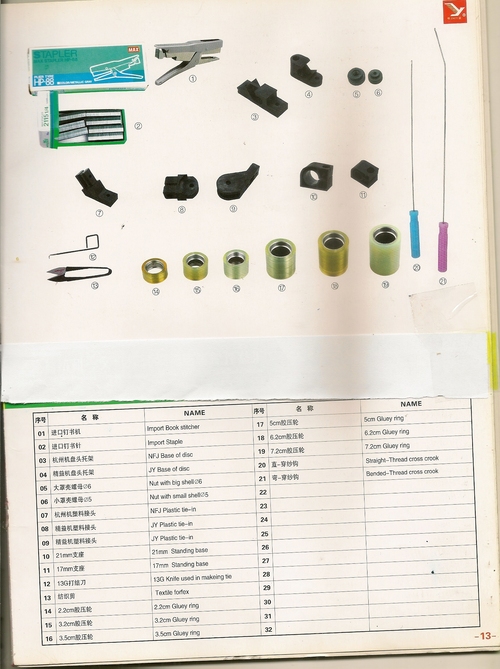

NEEDL LOOM SPARE PART

Price Range 50000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Textile Machinery Spare

Weight (kg) : Varies (Typically 100500g each part)

Type : Other, Needle Loom Spare Part

Color : Other, Metallic Silver/Grey

CROCHECT & NEEDLE LOOM SPARES

Price Range 50000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Crochet & Needle Loom Spares

Weight (kg) : Varies (Depending on Part)

Type : Other, Textile Machinery Spare Parts

Color : Other, Silver, Metallic Grey, Custom

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free