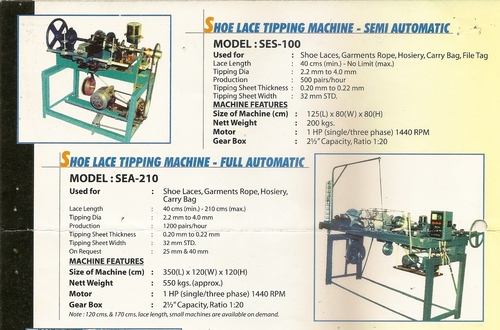

Shoe Lace Tipping Machine

Shoe Lace Tipping Machine Specification

- Frequency

- 50/60 Hz

- Product Type

- Shoe Lace Tipping Machine

- Material

- Mild Steel

- Machinery Type

- Automatic

- Capacity

- 5000-7000 pairs/8 hours

- Voltage

- 220-380 V

- Power

- 1 HP

- Dimension (L*W*H)

- 1200 x 800 x 1400 mm

- Weight

- 350 kg

- Color

- Blue & White

Shoe Lace Tipping Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

About Shoe Lace Tipping Machine

Being a client centric organization, our forte is to manufacture and export an utmost range of Shoe Lace Tipping Machine. These machines are used for attaching the metal objects on both sides of the shoe laces. Our Shoe Lace Tipping Machine is designed and developed under the guidance of veteran professionals by using optimum quality materials, in compliance with international quality of standards and norms. We hold the experts to customize these machines as per the needs of the clients.

Features:

- Low power consumption

- Rust proof body

- Durable service life

FAQs:

Q: What is a Shoe Lace Tipping Machine?

A: Shoe Lace Tipping Machine is a type of textile machinery that is used in the production of shoelaces. It is used to tip or add a reinforcement to the end of shoelaces to prevent fraying and improve durability.

Q: How does Shoe Lace Tipping Machine work?

A: Shoe Lace Tipping Machine typically works by first cutting the shoelaces to the desired length and then applying a reinforcement tip to the end of the shoelaces. The machine may use a heating process, such as heat-sealing, to bond the reinforcement tip to the shoelaces.

Q: What are the benefits of using a Shoe Lace Tipping Machine?

A: The benefits of using a Shoe Lace Tipping Machine include increased efficiency, improved quality, and consistent output. The machine allows for high-volume production of tipped shoelaces with consistent and accurate reinforcement, which can help to improve the overall quality and durability of the shoelaces.

Efficient and Versatile Shoelace Tipping

Designed for manufacturers and suppliers, the Shoe Lace Tipping Machine handles multiple lace materials including cotton, polyester, nylon, and PP. Its fully automatic operation ensures high throughput without sacrificing quality, making it ideal for high-volume requirements in the footwear industry.

Customizable and Safe Operation

Offering adjustable tipping lengths (2045 mm) and both hot and cold cutting, the machine provides flexibility to accommodate various lace styles. The PLC control system and emergency stop feature ensure process precision and user safety throughout continuous operations.

Robust Design and Reliable Support

Made from durable mild steel, this machine promises long-term reliability. With included installation support from the supplier, users can expect seamless setup and operation. Manual tape roller loading and electric heating further enhance the ease of use, making production straightforward and efficient.

FAQs of Shoe Lace Tipping Machine:

Q: How does the Shoe Lace Tipping Machine work for different lace materials?

A: The machine is compatible with cotton, polyester, nylon, and PP laces. Its adjustable tipping length (2045 mm) and dual cutting options (hot and cold) allow it to handle a variety of lace types with precision and consistency.Q: What is the process for adjusting the tipping length on the machine?

A: Adjustments to the tipping length can be made directly on the PLC control panel, allowing operators to select the desired length between 20 to 45 mm according to production needs.Q: When should I choose hot cutting versus cold cutting?

A: Hot cutting is generally preferred for synthetic laces such as polyester or nylon, as it seals the ends to prevent fraying. Cold cutting is suitable for natural fibers like cotton where heat might damage the material.Q: Where can installation support be obtained for this machine?

A: Installation support is provided by the supplier for clients across India, ensuring that the machine is set up correctly and operates smoothly from the start.Q: What are the operational benefits of the fully automatic mode and emergency stop feature?

A: The fully automatic mode enables high-speed production (6080 tips/minute) with minimal manual oversight. The emergency stop feature enhances safety by allowing immediate shutdown in case of any operational issues.Q: How is the tape roller loaded, and does it require any special tools?

A: Tape roller loading is manual, designed for easy access without specialized tools. Operators can quickly reload tape to maintain continuous production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Preparatory Machines Category

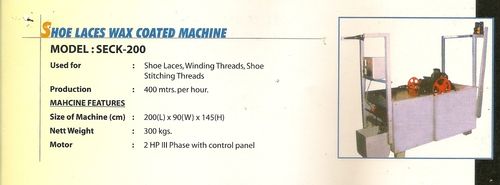

Shoe Laces Wax Coated Machine

Price Range 30000.00 - 300000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Other, Shoe Laces Wax Coated Machine

Color : Grey & Blue

Frequency : 50/60 Hz

Hook : Available

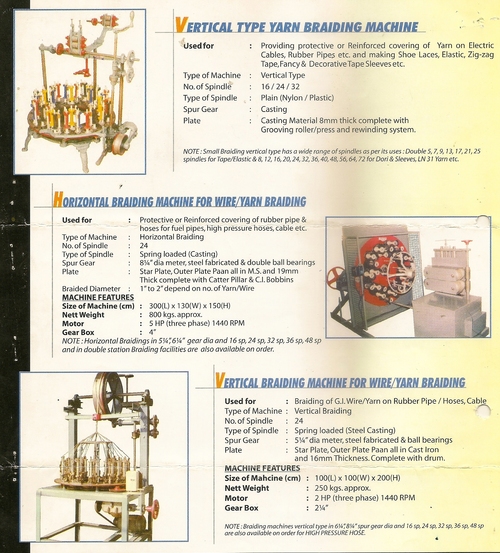

Yarn Braiding Machine

Price Range 30000.00 - 300000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Other, Yarn Braiding Machine

Color : BlueGrey

Frequency : 50 Hz

Hook : Available

Preparatory Machines

Price Range 30000.00 - 300000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Other, Preparatory Machine

Color : Blue/White

Frequency : 50 Hz

Hook : Automatic

Bow Machinery

Price Range 30000.00 - 300000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Other, Bow Machinery

Color : Blue & White

Frequency : 50 Hz

Hook : Steel Hook

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS