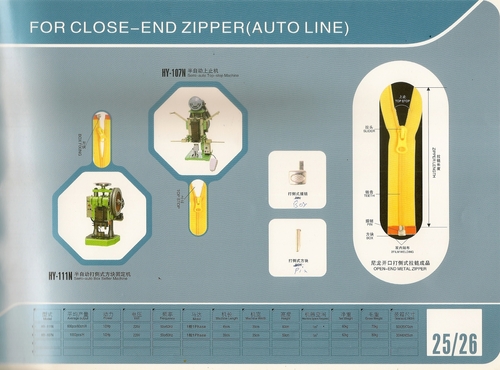

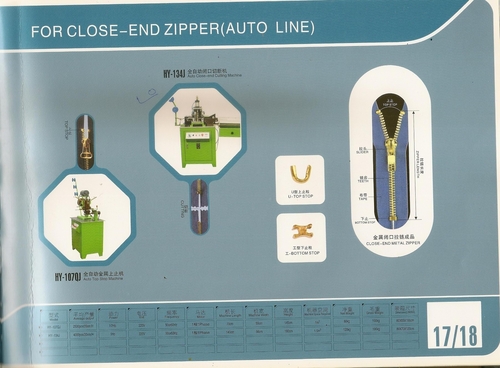

Metal Close end Zipper Machines

Metal Close end Zipper Machines Specification

- Type

- Metal Close End Zipper Machine

- Material

- Mild Steel, Stainless Steel

- Capacity

- 800-1000 Pieces/Hour

- Computerized

- Yes

- Automatic Grade

- Automatic

- Plate Type

- Flatbed

- Print Direction

- Uni-Directional

- Color Management

- Manual Adjust

- Control System

- PLC Control

- Working Temperature

- 0C - 55C

- Power

- 2.2 kW

- Size

- Standard

- Width

- Customized

- Weight (kg)

- 750

- Dimension (L*W*H)

- 2200 x 800 x 1700 mm

Metal Close end Zipper Machines Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 10 Days

About Metal Close end Zipper Machines

We have established ourselves among the foremost traders and suppliers of superior quality range of Metal Close-end Zipper Machines. These machines are used for sewing the zipper end in garment industries, and home furnishing sectors. Our Metal Close-end Zipper Machines are designed and manufactured by our professionals using supreme grade materials, as per the standards laid down by regulatory bodies. Being a quality centric organization, our offered products are at par with international quality standards at the mean time very nominal in price.

Features:

- Durable service life

- Sturdy construction

- Compact design

Advanced Automation for Higher Productivity

Benefit from automatic grade operation and computerized PLC controls that minimize manual intervention while ensuring stable performance. Its automatic chain feeding and integrated touch screen LCD make managing zipper production easy, enabling the production of 800-1000 pieces per hour with a single operator. This increases throughput and reduces labor costs for zipper manufacturers.

Reliable Safety and Centralized Lubrication

Every machine is equipped with overload protection, emergency stop functions, and a centralized automatic lubrication system. These features ensure operator safety and prolong equipment life. Maintenance is streamlined, and safety protocols are built-in, giving users peace of mind and consistent machine uptime.

Customizable and Compatible Design

With compatibility across various assembly lines and customizable width options, the Metal Close End Zipper Machine fits seamlessly into diverse production settings. Its flatbed plate type, mild steel/stainless steel build, and uni-directional print make it versatile for both small and large manufacturing environments.

FAQs of Metal Close end Zipper Machines:

Q: How does the automatic feeding system work on this metal close end zipper machine?

A: The machine uses an automatic chain feeding system that delivers zipper materials seamlessly to the processing units. This minimizes manual handling, improves efficiency, and ensures consistent zipper placement and operation throughout the production cycle.Q: What range of zipper sizes can this machine handle, and can it be adapted to different widths?

A: This model is designed to produce metal zippers ranging from #3 to #10 in size. Additionally, the machines width is customizable, allowing manufacturers to adjust to various production requirements for different zipper widths.Q: When is it necessary to use the emergency stop and what safety protocols are in place?

A: The emergency stop should be used if any abnormal operation or hazard is detected. Safety features include overload protection and an easily accessible emergency stop button, ensuring operators are protected during the production process.Q: Where can this machine be integrated within existing production lines?

A: This machine is compatible with a variety of zipper assembly lines, making it suitable for integration in both established and new manufacturing facilities. Its standard size and configurable features ensure seamless assembly line compatibility.Q: What is the process for routine maintenance and lubrication on this machine?

A: The centralized automatic lubrication system ensures that internal components are regularly and evenly lubricated. This system reduces the frequency of manual maintenance, though periodic checks according to the manufacturers guidance are still advised.Q: How does the PLC control system and touch screen interface benefit daily operation?

A: The advanced PLC control system integrated with a touch screen LCD panel offers clear operational visualization, simple adjustments, and efficient monitoring. This improves ease of use, minimizes user error, and enhances precision in zipper production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Zipper Machines Category

Fully automatic Plastic zipper machine

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Other, Fully Automatic

Weight (kg) : Approx. 950 kg

Size : Medium Industrial

Width : Max 350 mm material input

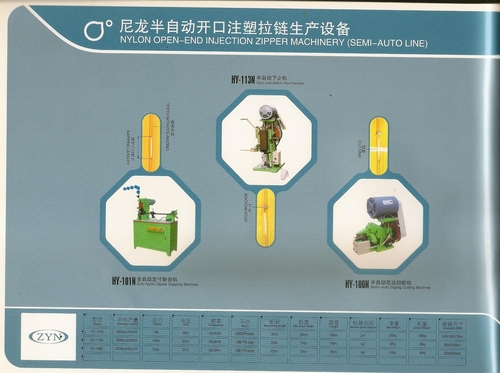

NYLON OPEN END INJECTION MACHINERY

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Weight (kg) : 1500 kg

Size : Standard Industrial

Width : 900 mm

Metal Zipper Machine

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Weight (kg) : 450 kg

Size : Standard Industrial

Width : 800 mm

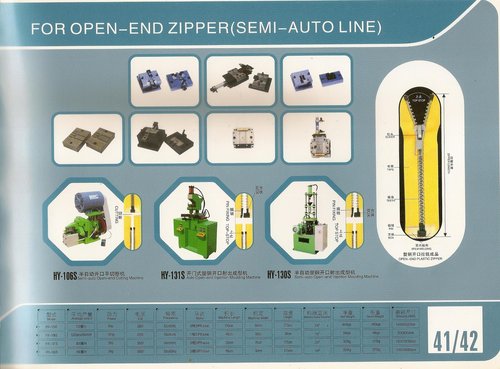

Semi Auto Line OPEN END ZIPPER MACHINERY

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : SemiAutomatic

Weight (kg) : 780 kg

Size : Standard Industrial

Width : Adjustable 3mm6mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free