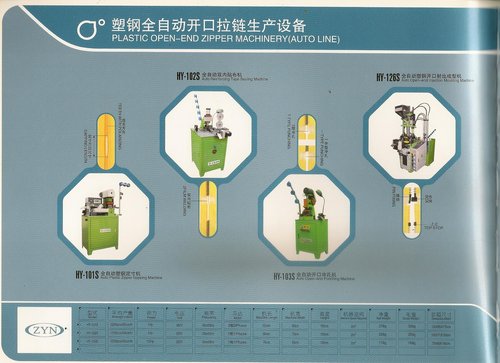

PLASTIC ZIPPER MACHINERY

PLASTIC ZIPPER MACHINERY Specification

- Type

- Plastic Zipper Making Machine

- Material

- Mild Steel

- Capacity

- 100-150 kg/hr

- Computerized

- Yes

- Automatic Grade

- Automatic

- Plate Type

- Flat Plate

- Print Direction

- Unidirectional

- Control System

- PLC Control

- Working Temperature

- 0-45C

- Power

- 8 kW

- Size

- Standard

- Width

- Customizable

- Weight (kg)

- 1500 kg

- Dimension (L*W*H)

- 3000 x 1200 x 1800 mm

- Production Speed

- 150 meters/minute

- Voltage

- 380V, 50/60Hz

- Machine Condition

- New

- Cooling System

- Water cooling

- Application

- Plastic Zipper Manufacturing

- Raw Material

- Granules/Pellets

- Noise Level

- 70 dB

- Operator Required

- 1 Person

- After Sales Service

- Available

- Lubrication System

- Automatic

- Drive Type

- Electric

PLASTIC ZIPPER MACHINERY Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 10 Days

About PLASTIC ZIPPER MACHINERY

Commercial Applications & Unique Advantages

PLASTIC ZIPPER MACHINERY is ideal for a variety of commercial uses, especially in mass production environments within the plastic industry. Simple to operaterequiring just one operatorit processes granules or pellets with unmatched efficiency. Its competitive advantages include automatic lubrication, water cooling system, and PLC control, ensuring reliability and longevity. The machinerys customizable width and computerized, automatic grade design provide flexibility, making it the preferred solution for zipper manufacturers.

Flexible Payment Terms & Global Shipment

Enjoy our special sale price and seamless logistics support when purchasing the PLASTIC ZIPPER MACHINERY. Multiple payment terms are available to facilitate easy transactions for our domestic market, primarily across India. We export through major FOB Ports, ensuring prompt and secure shipment to your destination. Every machinery order benefits from careful packaging and fast delivery, making your acquisition as smooth and efficient as your production process will be.

FAQs of PLASTIC ZIPPER MACHINERY:

Q: How does the automatic lubrication system benefit the user?

A: The automatic lubrication system reduces maintenance downtime, ensuring smooth operation and extending the lifespan of critical machine components without the need for frequent manual intervention.Q: What types of plastic raw materials can the machine process?

A: This machinery is designed to work efficiently with granules or pellets, offering adaptability to various plastic compounds that meet zipper production requirements.Q: When is after-sales service available for this machinery?

A: After-sales service is available following product installation, and includes operator training, technical support, and maintenance advice, ensuring ongoing satisfaction with your purchase.Q: Where can the PLASTIC ZIPPER MACHINERY be installed?

A: It can be installed safely in standard factory settings, as it is designed to operate at working temperatures between 0-45C and maintains low noise levels ( 70 dB), making it suitable for any industrial or commercial facility.Q: What is the production and operational process like for this machine?

A: The process begins by feeding granules or pellets into the machine; from there, the PLC system automates production at up to 150 meters per minute, with water cooling and automatic lubrication ensuring optimal performance throughout production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Zipper Machines Category

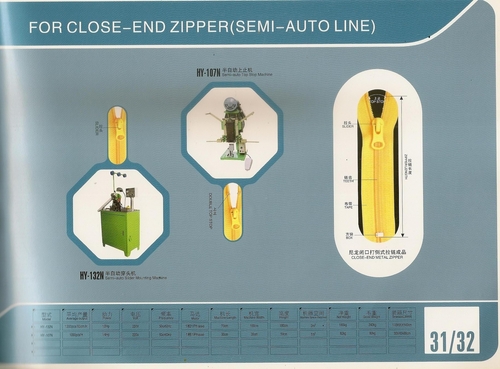

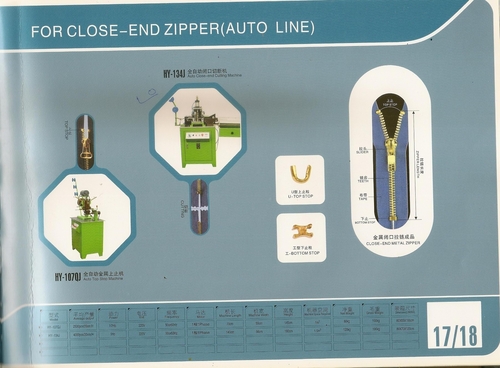

CLOSE END ZIPPER Machine

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Width : Customizable

Automatic Grade : Automatic

Computerized : Yes

Type : CLOSE END ZIPPER Machine

NYLON OPEN END INJECTION MACHINERY

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Width : 900 mm

Automatic Grade : Automatic

Computerized : Yes

Type : Open End Injection Machinery

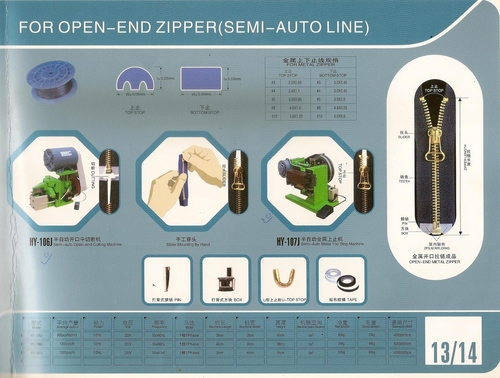

Semi Auto Line OPEN- END ZIPPER

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Width : Varies by zipper model (common: 2.5 cm 4.0 cm)

Automatic Grade : SemiAutomatic

Computerized : Yes

Type : SemiAuto Line OPENEND ZIPPER

Metal Zipper Machine

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Width : 800 mm

Automatic Grade : Automatic

Computerized : Yes

Type : Metal Zipper Machine

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS