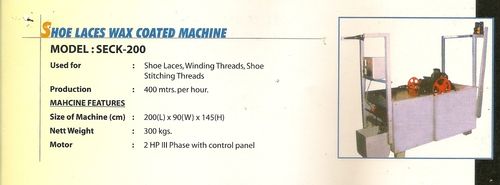

Shoe Laces Wax Coated Machine

Shoe Laces Wax Coated Machine Specification

- Hook

- Available

- Frequency

- 50/60 Hz

- Product Type

- Shoe Laces Wax Coated Machine

- Material

- Mild Steel Body & SS Contact Parts

- Machinery Type

- Automatic

- Capacity

- Up to 4000 pairs/day

- Voltage

- 220-240V AC

- Power

- 2 kW

- Dimension (L*W*H)

- 1800 x 900 x 1500 mm

- Weight

- Approx 650 kg

- Color

- Grey & Blue

Shoe Laces Wax Coated Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

About Shoe Laces Wax Coated Machine

Capitalizing on our vast knowledge of the arena, we have established ourselves as an eminent manufacturer and supplier of Shoe Laces Wax Coated Machine. Our machines are made by our expert engineers using best quality materials and cutting edge technology. Our Shoe Laces Wax Coated Machine is used for coating wax over shoe laces, winding threads and shoe stitch threads. We adhere to the parameters of the national and international quality standards to provide the clients with utmost satisfaction in terms of quality.

Features:

- Modular design

- Low in maintenance

- Reliable operation

Efficient Wax Coating Technology

This state-of-the-art machine is tailored for seamless waxing of shoe laces, ensuring a uniform finish thanks to its electric heating and automatic thread feeding systems. With a production capability of up to 4,000 pairs per day, it is suitable for both flat and round laces, providing consistent results with minimal user intervention. The integration of a PLC-based digital control panel further enhances precision and workflow management.

Robust Build for Longevity

Constructed from mild steel and equipped with stainless steel contact parts, the machine promises longevity and wear resistance. The powder-coated finish adds an extra layer of protection. Despite its sturdy build, it boasts a low noise footprint, making it ideal for busy production environments.

Modern Automation Features

Built with a heavy duty induction motor, thermostat-regulated heating, digital controls, and a built-in blower, this machine is engineered for uninterrupted, efficient operation. The automatic feeding mechanism reduces manual labor and increases output efficiency, ideal for large-scale manufacturers and exporters.

FAQs of Shoe Laces Wax Coated Machine:

Q: How does the Shoe Laces Wax Coated Machine operate?

A: The machine uses an automatic thread feeding system and a digital PLC control panel to guide shoe laces through an electric heating unit where wax coating is applied. The process is fully automated, requiring minimal manual intervention and ensuring consistent, high-quality finishes.Q: What types of shoe laces can be processed with this machine?

A: This wax coating machine accommodates both round and flat shoe laces. Its adjustable components and precise feed mechanism make it suitable for a range of lace thicknesses and lengths, commonly used in footwear manufacturing.Q: When is this machine best utilized in the production process?

A: The machine should be used after lace formation and before packaging. Its ideal for the final waxing stage, where consistent coating and cooling enhance the quality and durability of the finished laces.Q: Where is the machine commonly installed?

A: It is typically installed in footwear manufacturing units, specialty lace production workshops, and export factories in India or international locations. Its moderate dimensions allow for easy integration into existing production lines.Q: What is the process for waxing laces in this machine?

A: Shoe laces are automatically fed into the heated waxing chamber, coated uniformly, and then passed through a cooling section featuring a built-in blower. The finished laces are collected at the output for further processing or packaging.Q: How is the finished product quality ensured?

A: The electric heating system with thermostat control keeps the wax at optimal temperature, ensuring even application, while the cooling blower helps set the coating and maintain lace integrity. The PLC-based controls allow precise adjustments for consistent results.Q: What are the key benefits of using this automatic waxing machine?

A: Benefits include high production rates (up to 4,000 pairs daily), reduced manual labor due to automation, low noise operation, reliable digital controls, robust construction, and compatibility with both round and flat laces. These features combine for efficient, durable, and quality-driven production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Preparatory Machines Category

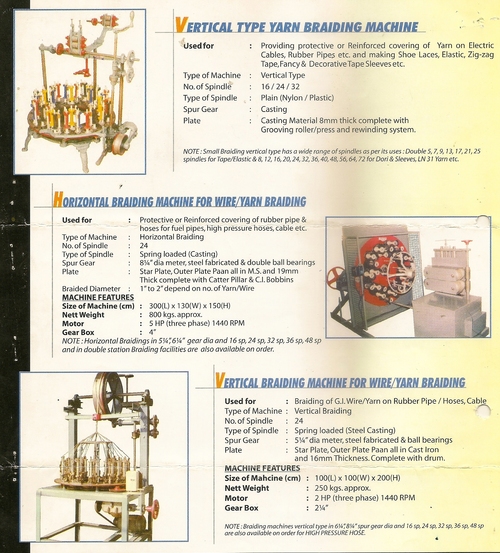

Yarn Braiding Machine

Price Range 30000.00 - 300000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 1700 x 1200 x 1800 mm

Product Type : Other, Yarn Braiding Machine

Frequency : 50 Hz

Color : BlueGrey

Preparatory Machines

Price Range 30000.00 - 300000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 2700 x 1200 x 1350 mm

Product Type : Other, Preparatory Machine

Frequency : 50 Hz

Color : Blue/White

Bow Machinery

Price Range 30000.00 - 300000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : 1850 x 800 x 1200 mm

Product Type : Other, Bow Machinery

Frequency : 50 Hz

Color : Blue & White

Bobbin Winder- Six spindles

Price Range 30000.00 - 300000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Dimension (L*W*H) : Approx. 1800 x 500 x 1000 mm

Product Type : Other, Bobbin Winder Six Spindles

Frequency : 50 Hz

Color : Blue & White

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS