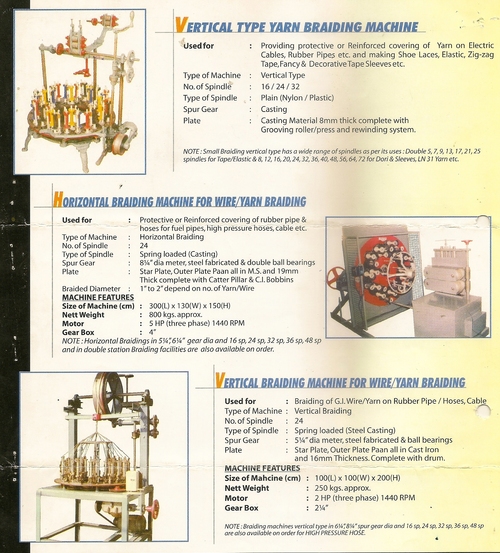

Yarn Braiding Machine

Yarn Braiding Machine Specification

- Hook

- Available

- Frequency

- 50 Hz

- Product Type

- Yarn Braiding Machine

- Material

- Mild Steel

- Machinery Type

- Automatic

- Capacity

- 20-40 meters/minute

- Voltage

- 220-440 V

- Power

- 2 HP

- Dimension (L*W*H)

- 1700 x 1200 x 1800 mm

- Weight

- 800 kg

- Color

- Blue-Grey

- Noise Level

- Low

- Lubrication System

- Centralized automatic lubrication

- Control Panel

- PLC Controlled

- Production Speed

- Adjustable

- Number of Spindles

- 16, 24, 32, 48 (as per model)

- Braiding Diameter Range

- 2 mm 25 mm

- Application

- Braiding round, flat, hollow ropes & cords

- Applicable Yarn Types

- Cotton, Polyester, Nylon, PP, Others

- Operation Mode

- Semi-automatic / Automatic

Yarn Braiding Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

About Yarn Braiding Machine

With an eternal back-up of our dedicated team, we have been manufacturing a superior range of Yarn Braiding Machine. Our Yarn Braiding Machine is used for proving a protective layer of yarn on electrical cable & rubber pipes, and for producing fancy tape, zigzag tape & shoe laces. Our Yarn Braiding Machine is manufactured by our professionals as per the set industry norms using supreme grade materials. Furthermore, to attain maximum satisfaction of the patron, our range is delivered to their destination in stipulated period of time.

Features:

- Rugged constriction

- Advance service life

- Portable design

Versatile Braiding Capability

With a broad braiding diameter range (2 mm to 25 mm) and selectable spindle options (16, 24, 32, or 48), this machine handles diverse requirements in one unit. Suitable for multiple yarn typesfrom cotton and polyester to nylon and PPit delivers consistent braids in round, flat, and hollow forms, meeting varied industry standards.

Efficient and User-Friendly Operation

The PLC-controlled panel offers intuitive adjustments and monitoring, while both semi-automatic and automatic operation modes give operators flexibility. Centralized automatic lubrication ensures low-maintenance run times, and the machines low noise level creates a comfortable work environment for prolonged use.

Robust Construction and International Reach

Manufactured using high-grade mild steel and weighing 800 kg, this blue-grey machine is built for longevity. With dimensions of 1700 x 1200 x 1800 mm, its compact design is suitable for standard production floors. As a manufacturer, supplier, importer, and exporter based in India, the company delivers quality machinery to global clients.

FAQs of Yarn Braiding Machine:

Q: How does the Yarn Braiding Machine adjust to different production speeds and rope sizes?

A: The machine features an adjustable production speed control, allowing braiding output between 20 to 40 meters per minute. Braiding diameter can be set from 2 mm to 25 mm by selecting the appropriate model and adjusting spindle settings through the PLC panel.Q: What yarn materials are compatible with this braiding machine?

A: This machine supports a wide range of yarns, including cotton, polyester, nylon, polypropylene (PP), and others, ensuring flexibility for various braiding applications and product types.Q: Where is this Yarn Braiding Machine manufactured and available for export?

A: The machine is manufactured in India and offered for sale both domestically and internationally. As an exporter, importer, manufacturer, and supplier, the company caters to global clients seeking reliable braiding solutions.Q: What is the process for switching between semi-automatic and automatic operation modes?

A: Users can easily switch between semi-automatic and automatic modes via the PLC-controlled panel. This allows operators to choose manual intervention for custom jobs or full automation for high-volume production with reduced supervision.Q: How does the centralized automatic lubrication system benefit machine operation?

A: The centralized automatic lubrication system minimizes the need for manual maintenance, improves longevity of moving parts, and ensures smooth, continuous operation with lower chances of breakdown.Q: When is this machine most beneficial for textile manufacturers?

A: Textile manufacturers benefit most when producing a variety of braided ropes and cords in large volumes with consistent quality. The machines adjustable settings and broad applicability make it ideal for dynamic production requirements.Q: What applications does this machine suit beyond standard rope braiding?

A: Beyond making round ropes, the Yarn Braiding Machine is designed to braid flat and hollow cords, expanding its use in industries such as marine, industrial safety, craft, and textile product development.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Preparatory Machines Category

Bobbin Winder- Six spindles

Price Range 30000.00 - 300000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Blue & White

Machinery Type : Other, Automatic

Material : Mild Steel / Cast Iron Body

Product Type : Other, Bobbin Winder Six Spindles

Double Sided Digital Rotary Printing Machine

Price Range 30000.00 - 300000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Matte Silver and Blue

Machinery Type : Other, Rotary Digital Printing Machine

Material : Heavy Duty Metal Alloy

Product Type : Other, Double Sided Digital Rotary Printing Machine

Bow Machinery

Price Range 30000.00 - 300000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Blue & White

Machinery Type : Other, Industrial Textile Machinery

Material : Metal

Product Type : Other, Bow Machinery

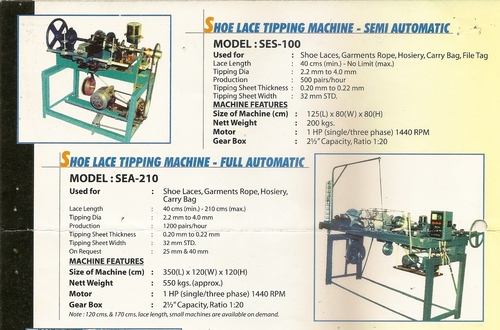

Shoe Lace Tipping Machine

Price Range 30000.00 - 300000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Blue & White

Machinery Type : Other, Automatic

Material : Mild Steel

Product Type : Other, Shoe Lace Tipping Machine

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS