GUIDE TUBE, BEEAM, WARPING MACHINE

GUIDE TUBE, BEEAM, WARPING MACHINE Specification

- Product Type

- Beam Warping Machine Guide Tube

- General Use

- For guiding yarns/beams in warping machines

- Type

- Guide Tube

- Capacity

- Optimized for Continuous Operation

- Weight (kg)

- 0.15 to 0.5 kg (Depending on Size)

- Computerized

- No

- Automatic

- No

- Drive Type

- Manual

- Dimension (L*W*H)

- Customizable As per Machine Requirement

- Feature

- Smooth Surface Finish, High Tensile Strength, Corrosion Resistant

- Color

- White/Grey/Metallic

- Control System

- Manual

- Operating Temperature Range

- Standard Room Temperature

- Corrosion Protection

- Yes

- Installation

- Easy Fit to Existing Machine Structure

- Application

- Used in textile machineryspecifically on beam warping machines for yarn guidance

- Packaging Type

- Standard Export Carton / Wooden Box

- Shape

- Hollow Cylinder

- Life Span

- Long Operating Life Under Normal Conditions

GUIDE TUBE, BEEAM, WARPING MACHINE Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

About GUIDE TUBE, BEEAM, WARPING MACHINE

Efficient Yarn Guidance in Textile Warping

Our GUIDE TUBE for beam warping machines is engineered to facilitate smooth and precise guidance of yarns and beams. Operating manually within standard room temperature ranges, this hollow cylindrical component is installed seamlessly on existing machine structures. Its optimized design handles continuous operation with ease, ensuring efficient application media for industrial textile machinery. Personalised dimensions allow the tube to match any machine requirement, enhancing the direction and use type for peak performance across textile production facilities.

Sample Policy, Certifications and Packaging Assurance

Benefit from our transparent sample policy and quality certifications, assuring you of compliance with industry standards. Each guide tube and related component is securely packaged in standard export cartons or wooden boxes for safe goods transport. Shipments are carefully managed to protect product integrity from origin to destination. Our packaging details focus on safeguarding your order throughout the shipment process, ensuring your purchase arrives in perfect conditionready for immediate installation and use in your textile machinery.

FAQs of GUIDE TUBE, BEEAM, WARPING MACHINE:

Q: How do you install the guide tube on a beam warping machine?

A: The guide tube is designed for easy fitting to existing machine structures. Simply insert and secure it as instructed by the machines manual, ensuring proper alignment for optimal yarn guidance.Q: What are the benefits of using this guide tube in textile machinery?

A: This guide tube offers high tensile strength, corrosion resistance, smooth surface finish, and a long operating life. These features contribute to efficient yarn guidance, reduced maintenance, and extended machine uptime.Q: What packaging options are available for shipment?

A: We provide standard export cartons or wooden boxes for packaging, tailored to safeguard the guide tubes during goods transport and ensure they reach you in excellent condition.Q: Can the guide tube be customised to different machine sizes and requirements?

A: Yes, the dimensions (length, width, height) of each guide tube are fully customisable to match your specific beam warping machine requirements, allowing for a personalised fit and enhanced efficiency.Q: When is it recommended to replace a guide tube on a warping machine?

A: Under normal conditions, the guide tube offers a long operating life. Replacement is generally recommended when signs of excessive wear, reduced performance, or physical damage are observed during routine maintenance checks.Q: Where are these guide tubes manufactured and supplied from?

A: All guide tubes are manufactured, exported, imported, and supplied by our facility in India, adhering to strict quality standards and competitive pricing for global markets.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

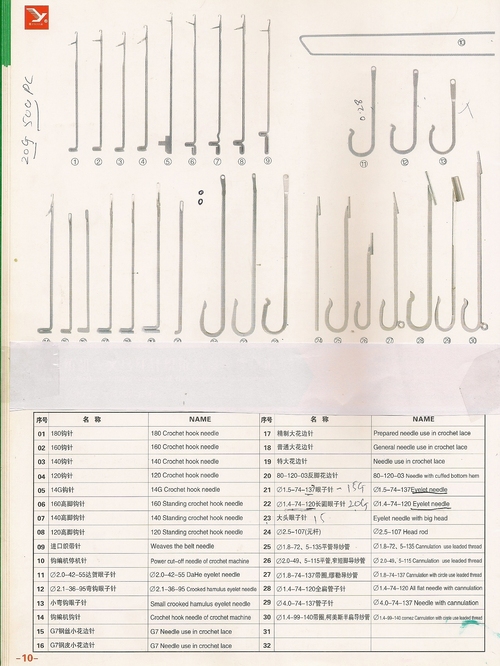

More Products in Crochet & Needle Loom Spare Part Category

Automatic Label Cutting and Endfold Machine

Price Range 50000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Other, Servo motor driven

Product Type : Textile label processing equipment

Color : Other, Industrial grey or custom

Material : Other, Suitable for fabric, satin, woven & printed labels

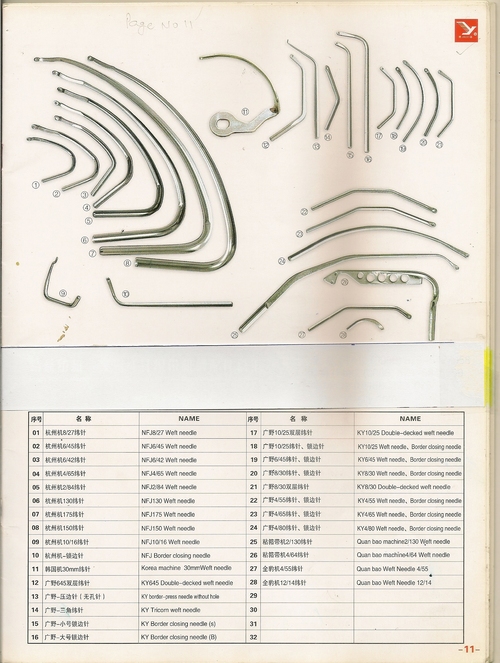

INDUTRIAL NEEDLLOOM SPARE PART

Price Range 50000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Other, Mechanical

Product Type : Industrial Needle Loom Spare Part

Color : Other, Silver, Black, or as required

Material : Other, Hardened Steel / Mild Steel (as per part)

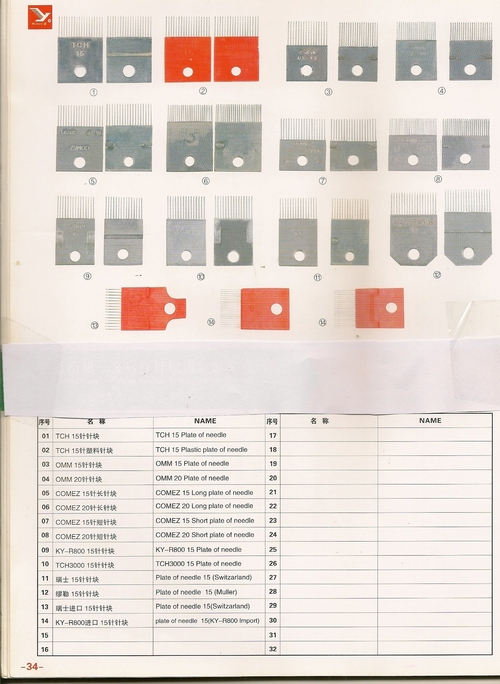

Circular Loom Spare Parts

Price Range 50000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Other, Mechanical

Product Type : Spare Parts

Color : Other, Silver, Grey, as per Part

Material : Other, Metal, Stainless Steel, Alloy Steel

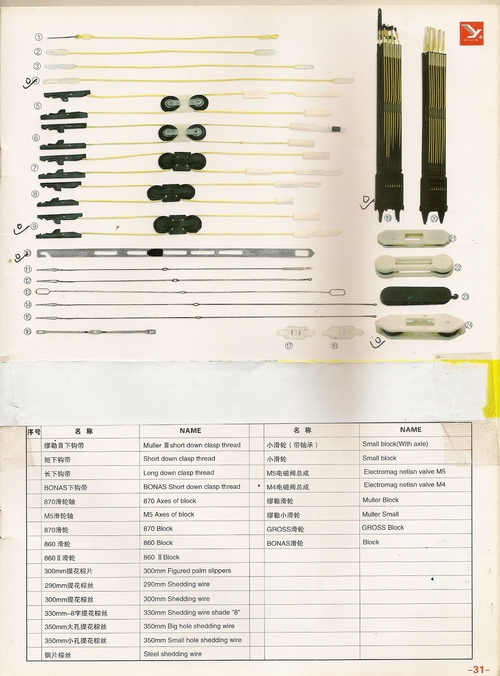

PLASTIC & METAL BLOCK

Price Range 50000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Other, Manual

Product Type : Plastic & Metal Block

Color : Other, Multicolor (Typically Blue and Silver/Grey)

Material : Other, Plastic and Metal

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS