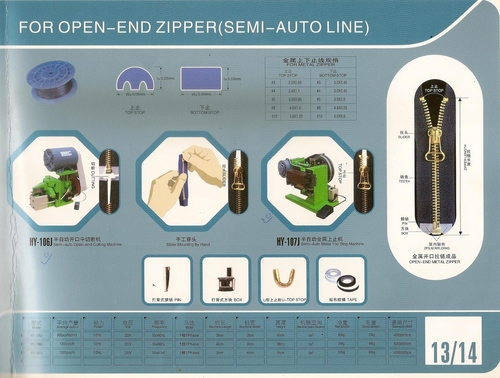

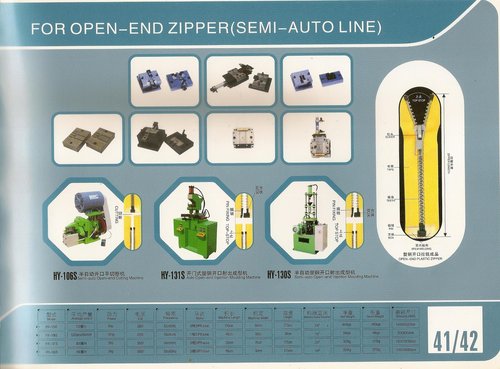

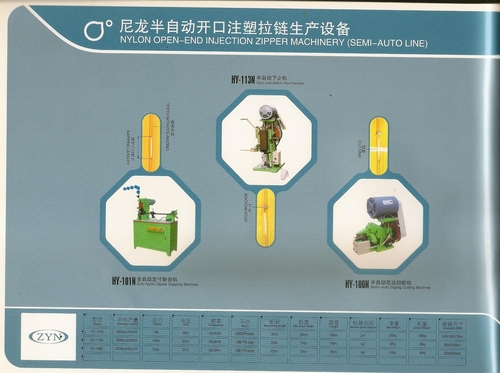

Semi Auto Line OPEN- END ZIPPER

Semi Auto Line OPEN- END ZIPPER Specification

- Type

- Semi-Auto Line OPEN-END ZIPPER

- Material

- High-strength plastic and metal alloy

- Capacity

- Up to 1800 pcs/hour

- Computerized

- Yes

- Automatic Grade

- Semi-Automatic

- Plate Type

- Standard extrusion

- Print Direction

- Bi-Directional

- Color Management

- Manual and preset

- Control System

- Touchscreen PLC control

- Working Temperature

- -5C to 45C

- Power

- 2.5 kW

- Size

- Medium-scale production line

- Width

- Varies by zipper model (common: 2.5 cm - 4.0 cm)

- Weight (kg)

- 620 kg

- Dimension (L*W*H)

- 3200 mm 1000 mm 1800 mm

Semi Auto Line OPEN- END ZIPPER Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 10 Days

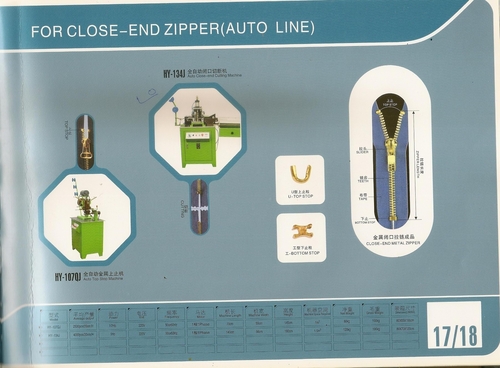

About Semi Auto Line OPEN- END ZIPPER

Advanced Features & Versatile Applications

The Semi Auto Line OPEN-END ZIPPER is renowned for its glorious efficiency and adjustability, featuring easy length and width modifications for each run. Made with high-strength materials, this line is perfect for diverse industriesjackets, bags, sporting goods, and luggage. Noteworthy extras include a premium touchscreen PLC control, overheat protection, and a large LCD status display. Its semi-automatic operation ensures all users have easy access, reducing labor while maintaining high productivity.

Premium Payment Terms & Reliable Supply

Valuation is straightforward with transparent, affordable pricing options tailored for exporters, importers, manufacturers, and suppliers in India. Prompt shipment is assured, and buyers benefit from flexible payment termsboth advance and post-delivery arrangements available on request. Supply ability meets medium to large-scale demands, with regular dispatch cycles. For those seeking product assurance, premium quality samples are available prior to bulk orders, ensuring satisfaction and optimal purchasing decisions.

FAQs of Semi Auto Line OPEN- END ZIPPER:

Q: How does the Semi Auto Line OPEN-END ZIPPER minimize labor costs?

A: This machine features an easy operator interface and continuous automatic feed, dramatically reducing the need for manual intervention and optimizing efficiency for every production run.Q: What applications is this zipper production line best suited for?

A: It is ideal for manufacturing zippers used in jackets, bags, sporting goods, and luggage, handling a range of zipper sizes from #3 to #8.Q: When should periodic maintenance be performed on the machine?

A: Periodic lubrication is recommended according to use frequency, while the redoubtable construction helps ensure low ongoing maintenance compared to similar machines.Q: Where can the machine be installed given its working temperature and voltage specs?

A: It supports a working temperature range of -5C to 45C and requires 220/380V (50/60 Hz) power, making it suitable for most standard manufacturing environments globally.Q: What safety features are included in the design?

A: Safety is paramount, with the system integrating an emergency stop button, overheat protection, and a noise level below 75 dB(A) for a secure and comfortable workplace.Q: How does the computerized system benefit production processes?

A: The touchscreen PLC control, bi-directional print capability, and large status display streamline setup changes, monitor real-time output, and enhance color management for reliable, consistent results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Zipper Machines Category

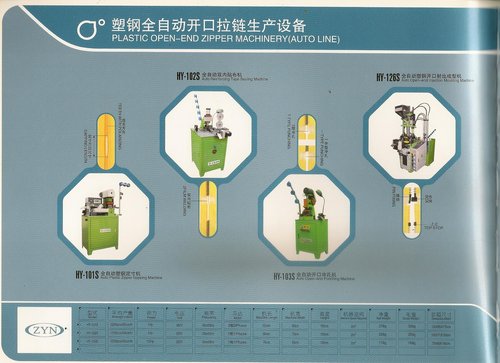

Fully automatic Plastic zipper machine

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 4070 pcs/min

Automatic Grade : Other, Fully Automatic

Computerized : Yes

Material : Stainless Steel, Aluminum

Metal Zipper Machine

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 8000 Pcs/Hour

Automatic Grade : Automatic

Computerized : Yes

Material : Highgrade Steel Alloy

PLASTIC ZIPPER MACHINERY

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 100150 kg/hr

Automatic Grade : Automatic

Computerized : Yes

Material : Mild Steel

Semi Auto Line OPEN END ZIPPER MACHINERY

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 25003000 pcs/hour

Automatic Grade : SemiAutomatic

Computerized : Yes

Material : Highgrade Alloy Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS