Metal Zipper Machine

Metal Zipper Machine Specification

- Type

- Metal Zipper Machine

- Material

- High-grade Steel Alloy

- Capacity

- 8000 Pcs/Hour

- Computerized

- Yes

- Automatic Grade

- Automatic

- Plate Type

- Flat Plate

- Print Direction

- Uni-Directional

- Color Management

- Digital Controller

- Control System

- PLC Control Panel

- Working Temperature

- 5C-35C

- Power

- 2.2 kW

- Size

- Standard Industrial

- Width

- 800 mm

- Weight (kg)

- 450 kg

- Dimension (L*W*H)

- 2200 mm x 800 mm x 1600 mm

Metal Zipper Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 10 Days

About Metal Zipper Machine

We are known as one of the leading manufacturers and exporters of an exceptional range of Metal Zipper Machine. These machines are wilder demanded in garment and bag making industries for designing metal zippers in various sizes and designs. In order to manufacture high quality Metal Zipper Machine, our professionals employ advanced machines and utilize quality tested material procured from the authentic vendors. We offer these machines to the clients at a reasonable price.

Features:

- Compact design

- Low maintenance

- User friendly interface

Precision and Efficiency in Zipper Production

With its advanced PLC control system and computerized features, the Metal Zipper Machine delivers high-speed, precision-driven zipper production. Its flat plate type and digital color control guarantee consistently uniform results, making it ideal for garment manufacturers seeking both quantity and quality.

Robust Safety and User-Friendly Operation

Engineered with an intuitive control panel and enhanced safety featuresincluding emergency stop and overload protectionthis machine ensures both operator security and operational reliability. Requiring just a single operator, its automated functions streamline workflow while minimizing intervention.

Durable Build and Industry-Ready Design

Manufactured from high-grade steel alloy and finished with a powder-coated surface, this machine is built for long-term use in industrial settings. The standard dimensions and manageable weight allow easy integration into existing production lines, supporting large-scale zipper manufacturing for exporters, importers, and suppliers.

FAQs of Metal Zipper Machine:

Q: How does the automatic lubrication system work in the Metal Zipper Machine?

A: The automatic lubrication system ensures all moving parts are continuously oiled, reducing wear and maintenance needs while extending machine lifespan without manual intervention.Q: What is the production process utilized by this zipper machine?

A: The machine uses a cold press method combined with computerized controls, enabling precise shaping and assembly of zipper chains for continuous, high-volume output suitable for garment applications.Q: When is maintenance required for the Metal Zipper Machine?

A: Thanks to the automated lubrication system and robust build, routine maintenance is minimized. However, regular visual inspections and periodic servicing as per the manufacturers guidelines are recommended to ensure optimal performance.Q: Where can the Metal Zipper Machine be installed within a manufacturing facility?

A: With its standard industrial dimensions (2200 mm x 800 mm x 1600 mm), this machine fits seamlessly into most garment zipper production lines, requiring standard electrical connections and a working temperature range of 5C to 35C.Q: What are the benefits of the digital color management and PLC control panel?

A: Digital color management ensures precise and repeatable color consistency for zippers, while the PLC control panel facilitates automated and accurate process control, optimizing both product quality and production speed.Q: How is operator safety ensured during machine operation?

A: Key safety features such as emergency stop and overload protection are integrated to instantly halt operations in case of emergencies, protecting the single operator and the machine itself.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Zipper Machines Category

Fully automatic Plastic zipper machine

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Size : Medium Industrial

Dimension (L*W*H) : 3450 880 1850 mm

Material : Stainless Steel, Aluminum

Weight (kg) : Approx. 950 kg

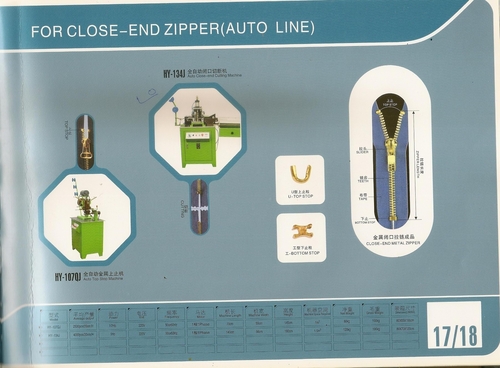

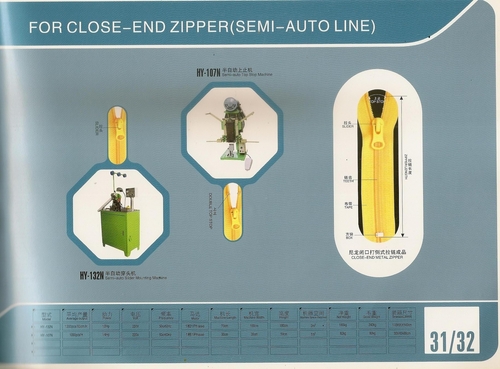

Metal Close end Zipper Machines

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Size : Standard

Dimension (L*W*H) : 2200 x 800 x 1700 mm

Material : Mild Steel, Stainless Steel

Weight (kg) : 750

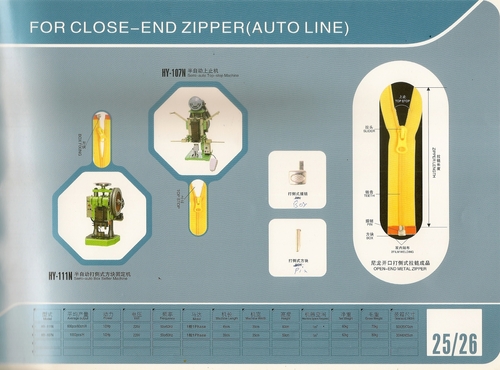

CLOSE END ZIPPER Machine

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Size : Standard

Dimension (L*W*H) : 1750 x 800 x 1800 mm

Material : Stainless Steel

Weight (kg) : 350 kg

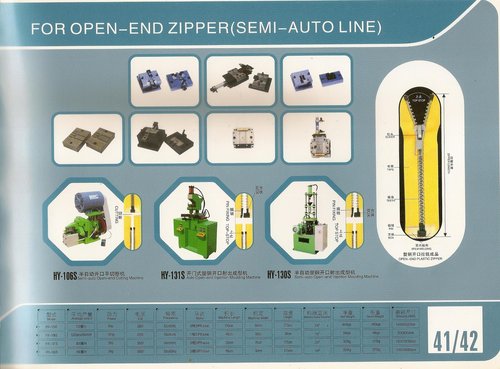

NYLON OPEN END INJECTION MACHINERY

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Size : Standard Industrial

Dimension (L*W*H) : 3200 mm x 900 mm x 1800 mm

Material : High Grade Nylon

Weight (kg) : 1500 kg

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS