NYLON OPEN END INJECTION MACHINERY

NYLON OPEN END INJECTION MACHINERY Specification

- Type

- Open End Injection Machinery

- Material

- High Grade Nylon

- Capacity

- Adjustable Up To 240 pcs/hour

- Computerized

- Yes

- Automatic Grade

- Automatic

- Plate Type

- Injection Molded Plate

- Print Direction

- Horizontal

- Color Management

- Digital Control

- Control System

- PLC Based

- Working Temperature

- Up to 80C

- Power

- 7.5 kW

- Size

- Standard Industrial

- Width

- 900 mm

- Weight (kg)

- 1500 kg

- Dimension (L*W*H)

- 3200 mm x 900 mm x 1800 mm

- Mould Thickness

- 150 350 mm

- Machine Structure

- Heavy Duty Steel Frame

- Ejector Force

- 40 kN

- Cooling Water Consumption

- 600 L/h

- Heating Zones

- 4

- Cycle Time

- 30 60 seconds

- Screw Diameter

- 45 mm

- Applications

- Nylon open end product manufacturing (e.g. zippers, fasteners)

- Voltage

- 380 V / 3 Phase / 50 Hz

- Clamping Force

- 80 100 tons

- Oil Tank Capacity

- 300 L

- Mould Opening Stroke

- 280 mm

- Injection Pressure

- 1400 bar

NYLON OPEN END INJECTION MACHINERY Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 10 Days

About NYLON OPEN END INJECTION MACHINERY

Precise Application Across Industries

NYLON OPEN END INJECTION MACHINERY is widely utilised by manufacturers, exporters, and suppliers involved in nylon zipper and fastener production. Its site of application spans textile, garment, and accessory industries, where robust open end components are required. Suitable for both specific nylon injection molding and general industrial usage, the machines digitally managed process ensures versatility and superior component quality. Its peerless capabilities also make it ideal for high-volume production environments demanding consistency and efficiency.

Packaging Detail and Export Excellence

The machinery is securely packed in reinforced wooden crates, ensuring safe transit and prompt dispatch. Dispatched promptly after order completion, our equipment serves major export markets in Asia, Africa, Europe, and Middle East, distinguished by its certification to industry standards. Customers rate our export packaging highly for strength and tamper resistance, ensuring every order arrives intact and ready for immediate installation. Order completion and rapid shipment are guaranteed with every transaction.

FAQs of NYLON OPEN END INJECTION MACHINERY:

Q: How does the computerized system enhance the efficiency of the NYLON OPEN END INJECTION MACHINERY?

A: The advanced PLC-based control system streamlines operation, ensuring precise process management, higher productivity, and minimal downtime. Digital control allows for easy adjustments, leading to consistently superior results in nylon product manufacturing.Q: What applications is this machinery best suited for?

A: This machinery is specifically designed for producing nylon open end items such as zippers and fasteners, making it ideal for garment, textile, and accessory manufacturing sectors.Q: Where can NYLON OPEN END INJECTION MACHINERY be installed?

A: It can be installed in industrial facilities and manufacturing plants focused on nylon products, particularly where high-volume, precision molding is required.Q: What is the process for ordering and receiving the machinery?

A: After you place an order, the machinery is packaged carefully for export and dispatched promptly. Shipments are completed upon order fulfillment, ensuring timely delivery to your specified location.Q: What are the main benefits of using this injection machinery?

A: Users benefit from adjustable production capacity, automatic operation, high-quality nylon output, and reliable service, boosting overall manufacturing efficiency and product standardization.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

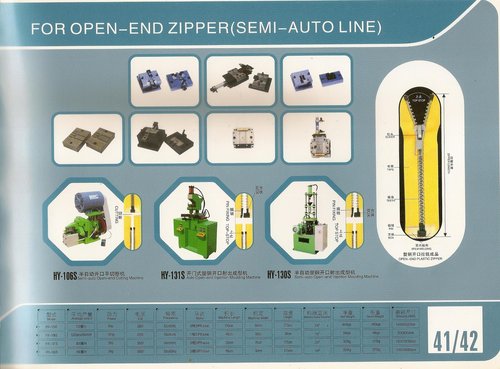

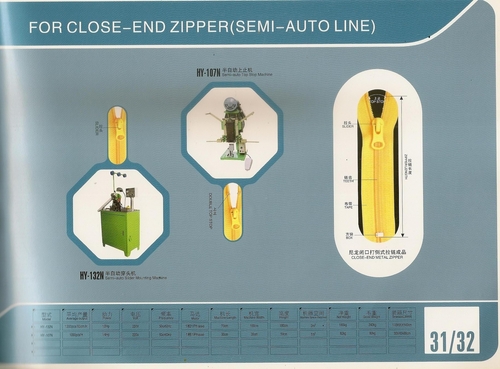

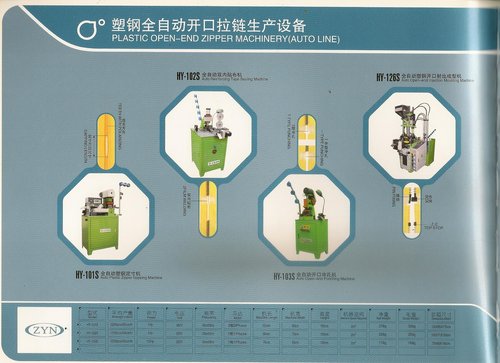

More Products in Zipper Machines Category

Fully automatic Plastic zipper machine

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Size : Medium Industrial

Automatic Grade : Other, Fully Automatic

Width : Max 350 mm material input

Weight (kg) : Approx. 950 kg

CLOSE END ZIPPER Machine

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Size : Standard

Automatic Grade : Automatic

Width : Customizable

Weight (kg) : 350 kg

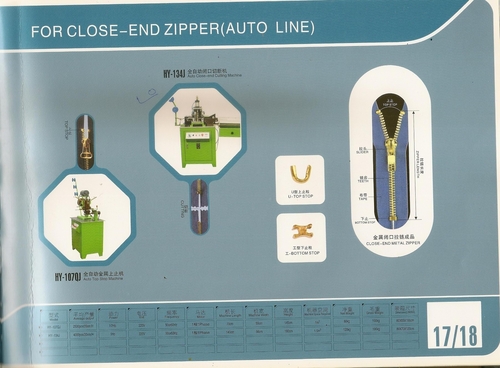

Metal Zipper Machine

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Size : Standard Industrial

Automatic Grade : Automatic

Width : 800 mm

Weight (kg) : 450 kg

PLASTIC ZIPPER MACHINERY

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Size : Standard

Automatic Grade : Automatic

Width : Customizable

Weight (kg) : 1500 kg

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS