Fully automatic Plastic zipper machine

Fully automatic Plastic zipper machine Specification

- Type

- Fully Automatic Plastic Zipper Machine

- Material

- Stainless Steel, Aluminum

- Capacity

- 40-70 pcs/min

- Printing Speed

- Up to 120 m/min

- Computerized

- Yes

- Automatic Grade

- Fully Automatic

- Plate Type

- Plastic Module

- Print Direction

- Bidirectional

- Ink Type

- Specialized Zipper Ink, Thermal Ink

- Color Management

- CMYK, Single/Double Color Options

- Control System

- PLC Touchscreen Control

- Working Temperature

- 0-45C

- Power

- 4.5 kW

- Size

- Medium Industrial

- Width

- Max 350 mm material input

- Weight (kg)

- Approx. 950 kg

- Dimension (L*W*H)

- 3450 880 1850 mm

- Air Source

- 0.5-0.7 MPa Required

- Cutting Mechanism

- Precision Pneumatic Cutter

- Main Shaft Speed

- Variable Frequency Adjustable

- Noise Level

- 75 dB(A)

- Safety Features

- Emergency Stop, Safety Guard

- Operation Mode

- Touch Screen + Button Panel

- Machine Frame

- Heavy-duty Welded Steel Frame

- Usage/Application

- Garment Accessories, Bag, Luggage, Textile

- Output Zipper Types

- Nylon, Resin, Invisible, Plastic Zippers

- Feeding Method

- Automatic Material Feeding

- Lubrication System

- Centralized Automatic Lubrication

- Drive System

- Servo Motor Drive

Fully automatic Plastic zipper machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 10 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

About Fully automatic Plastic zipper machine

With our modernized and core infrastructure facility, we are certain to provide highest quality range of Fully Automatic Plastic Zipper Machine. Our experts design these machines from top notch materials at our state of the art machining facility. Ideal for sewing zipper in pants, jeans, bags and plastic covers, our Fully Automatic Plastic Zipper Machine is widely used in garnet and packaging industries. We hold the experts to customize these machines as per the exact needs of the clients.

Features:

- Zero maintenance

- Reliable performance

- Durable design

High-Efficiency Zipper Production

With a capacity to produce 4070 zippers per minute, the Fully Automatic Plastic Zipper Machine meets large-scale manufacturing demands. Its servo motor drive and variable frequency ensure smooth operation, adaptable to several types of zippers like nylon, resin, invisible, and plastic. The robust machine frame and modular control design guarantee consistent performance and long service life, even under intensive use.

Advanced Control and Operation

The intuitive PLC touchscreen, combined with traditional button panel controls, facilitates effortless operation and parameter adjustment. This user-centric interface, along with features such as bidirectional printing, color management with CMYK options, and specialized ink compatibility, maximizes operator efficiency and production flexibility.

Safety, Durability, and Maintenance

Safety guards and the emergency stop function prioritize operator well-being, while centralized automatic lubrication supports long-lasting, low-maintenance performance. The heavy-duty welded steel frame resists vibration and wear, and precision pneumatic cutting ensures clean, repeatable results. An accessible design makes routine checks straightforward for ongoing reliability.

FAQs of Fully automatic Plastic zipper machine:

Q: How does the automatic feeding and cutting process work on this zipper machine?

A: The machine incorporates an automatic material feeding system alongside a precision pneumatic cutting mechanism. Materials are efficiently guided into the machine, where zippers are formed, cut to size with pneumatic accuracy, and finishedall without manual intervention, ensuring consistent quality and productivity.Q: What types of zippers can be produced using this machine?

A: This fully automatic machine handles the manufacturing of nylon, resin, invisible, and plastic zippers, offering flexibility to meet the demands of garment, bag, luggage, and textile production.Q: When should the centralized automatic lubrication system be checked or maintained?

A: The centralized automatic lubrication system is designed to run continuously while the machine operates, delivering necessary lubrication to all key components. Regular visual inspections during routine maintenance schedulestypically once a weekhelp ensure it remains functioning optimally.Q: Where is this machine most commonly used?

A: Manufacturers in the garment accessories, bag, luggage, and general textile industries use this machine extensively, particularly in export and supply operations due to its high-speed, reliable performance, and versatility for multiple zipper types.Q: What benefits does the PLC touchscreen control system provide?

A: The PLC touchscreen control allows for precise, on-the-fly adjustments of machine parameters. It simplifies setting up for different zipper specifications and print options, enhances usability, and minimizes production downtime through intuitive error diagnostics.Q: How does the machine manage noise and operator safety?

A: Designed with noise reduction features to keep operational noise below 75 dB(A), the machine also offers safety guards and an emergency stop function, minimizing risk and creating a safer work environment for operators.Q: What is the recommended operating environment for this machine?

A: For optimal performance, the machine should be operated within a temperature range of 045C and supplied with an air pressure between 0.50.7 MPa. These parameters help ensure consistent output quality and extend the lifetime of the machine components.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Zipper Machines Category

NYLON OPEN END INJECTION MACHINERY

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Material : High Grade Nylon

Control System : Other, PLC Based

Weight (kg) : 1500 kg

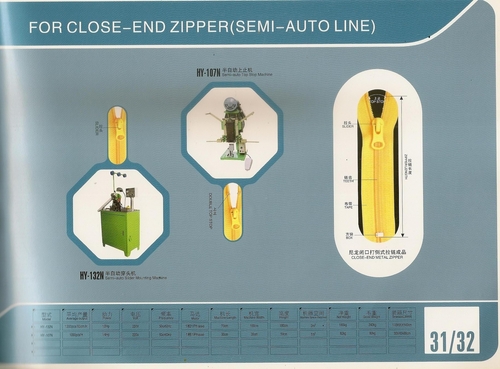

CLOSE END ZIPPER Machine

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Material : Stainless Steel

Control System : Other, PLC Touch Panel

Weight (kg) : 350 kg

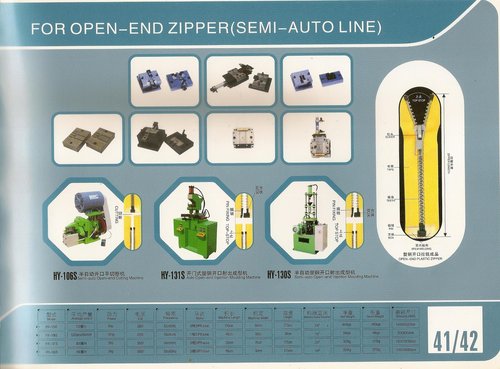

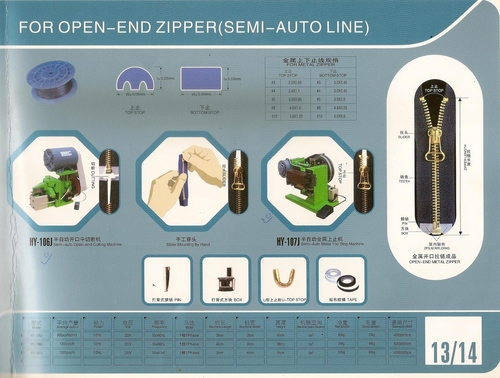

Semi Auto Line OPEN- END ZIPPER

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Material : Highstrength plastic and metal alloy

Control System : Other, Touchscreen PLC control

Weight (kg) : 620 kg

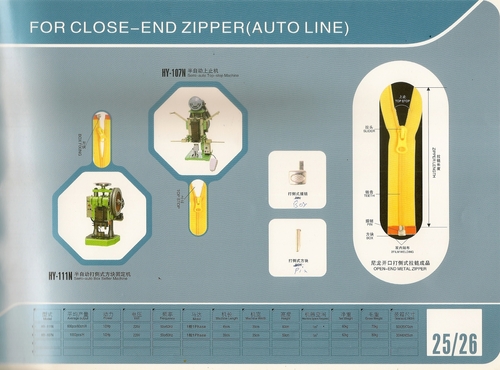

Metal Close end Zipper Machines

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : Yes

Material : Mild Steel, Stainless Steel

Control System : PLC Control

Weight (kg) : 750

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS