Preparatory Machines

Preparatory Machines Specification

- Hook

- Automatic

- Frequency

- 50 Hz

- Product Type

- Preparatory Machine

- Material

- Stainless Steel

- Machinery Type

- Textile Processing

- Capacity

- 1500 kg/hr

- Voltage

- 380 V

- Power

- 7.5 kW

- Dimension (L*W*H)

- 2700 x 1200 x 1350 mm

- Weight

- 1600 kg

- Color

- Blue/White

- Surface Finish

- Powder Coated

- Speed

- Adjustable (up to 2200 RPM)

- Safety Features

- Emergency Stop, Overload Protection

- Feed Material

- Cotton, Synthetic

- Lubrication System

- Centralized Oil Lubrication

- Noise Level

- <75 dB

- Additional Product Specification Heading

- Additional Product Specifications

- Drive Type

- V-belt Driven

- Automation Grade

- Fully Automatic

- Working Type

- Continuous

- Usage/Application

- Textile Yarn Preparation

- Control Panel

- Digital Touchscreen

Preparatory Machines Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

About Preparatory Machines

Versatile Application in Textile Yarn Preparation

Preparatory Machines are crafted for both specific and general use within textile yarn production facilities. They efficiently handle cotton and synthetic materials, optimizing the area of application to spinning, carding, and blending stages. With a splendid surface finish, these machines suit a diverse range of textile materials and surfaces, ensuring consistent yarn quality and performance in every batch.

Reliable Supply and Swift Shipment Guaranteed

With a robust outlay and capacity to deliver, our Preparatory Machines are available for quick dispatch from major FOB ports in India. As a trusted exporter, importer, manufacturer, and supplier, we ensure shipment protocols are streamlined for minimal wait times. Samples are available upon request, allowing you to evaluate the ineffable quality and consistency before placing bulk orders.

FAQs of Preparatory Machines:

Q: How does the fully automatic function of the Preparatory Machine enhance textile production?

A: The fully automatic system streamlines the yarn preparation process, reducing manual intervention, increasing operational efficiency, and minimizing errors, enabling continuous, high-quality output.Q: What types of materials can be processed using this machine?

A: This machine is compatible with both cotton and synthetic fibers, offering splendid adaptability for various textile manufacturing requirements.Q: Where is the ideal place to install the Preparatory Machine in a textile facility?

A: It is best positioned in the yarn preparatory section, where spinning, blending, and carding operations are performed, maximizing its usefulness and accessibility.Q: When can I expect shipment and delivery of my order?

A: Orders are processed for quick dispatch from our FOB port in India, with shipment timelines depending on destination and order volume. Typical lead times are communicated once the order is confirmed.Q: What safety features are included in the machine?

A: The machine is equipped with emergency stop and overload protection, ensuring operator safety and machine durability during continuous operation.Q: How can users adjust the speed of the machine during operations?

A: Users can easily set and modify the machine speedup to 2200 RPMvia the digital touchscreen control panel for precise results based on application requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Preparatory Machines Category

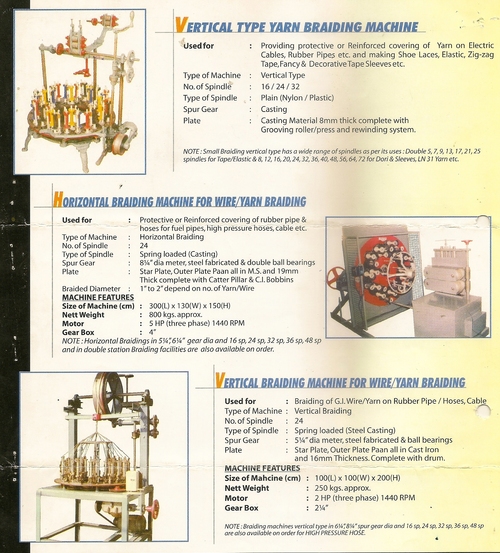

Yarn Braiding Machine

Price Range 30000.00 - 300000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Machinery Type : Other, Automatic

Dimension (L*W*H) : 1700 x 1200 x 1800 mm

Material : Mild Steel

Product Type : Other, Yarn Braiding Machine

Double Sided Digital Rotary Printing Machine

Price Range 30000.00 - 300000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Machinery Type : Other, Rotary Digital Printing Machine

Dimension (L*W*H) : 5500 mm 2500 mm 2300 mm

Material : Heavy Duty Metal Alloy

Product Type : Other, Double Sided Digital Rotary Printing Machine

Bobbin Winder- Six spindles

Price Range 30000.00 - 300000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Machinery Type : Other, Automatic

Dimension (L*W*H) : Approx. 1800 x 500 x 1000 mm

Material : Mild Steel / Cast Iron Body

Product Type : Other, Bobbin Winder Six Spindles

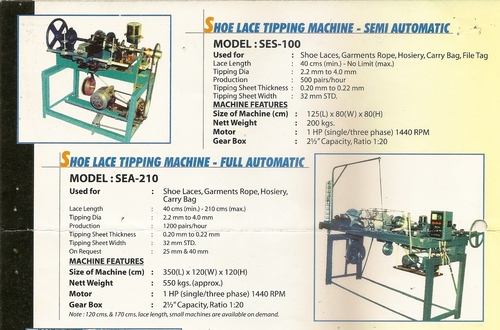

Shoe Lace Tipping Machine

Price Range 30000.00 - 300000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Machinery Type : Other, Automatic

Dimension (L*W*H) : 1200 x 800 x 1400 mm

Material : Mild Steel

Product Type : Other, Shoe Lace Tipping Machine

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS