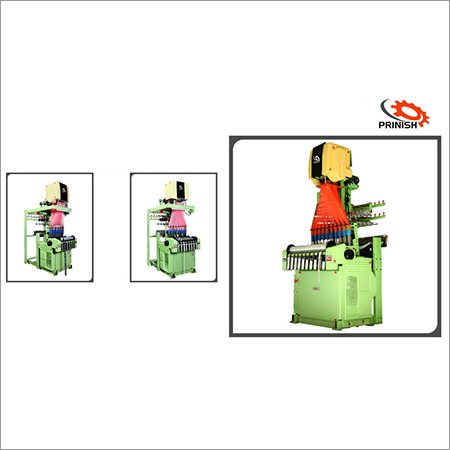

Warping Machine

Warping Machine Specification

- Type

- Automatic Warping Machine

- Material

- Mild Steel

- Capacity

- 1000 meters/hour

- Printing Speed

- 1000 m/h

- Computerized

- Yes

- Automatic Grade

- Automatic

- Plate Type

- Cylinder Plate

- Print Direction

- Bidirectional

- Control System

- PLC Controlled

- Working Temperature

- 5C - 40C

- Power

- 7.5 kW

- Size

- Large

- Width

- Up to 2800 mm

- Weight (kg)

- 3200 kg

- Dimension (L*W*H)

- 3800 x 2800 x 1800 mm

- Noise Level

- Low

- Beaming Device

- Heavy Duty, Automatic

- Voltage

- 380V, 50/60Hz

- Application

- Textile Yarn Warping

- Lubrication

- Automatic Lubrication System

- Main Motor

- AC Servo Motor

- Suitable Yarn Type

- Cotton, Polyester, Viscose, Blend

- Mounting Type

- Floor Standing

- Drum Material

- Alloy Steel/Surface Hard Chrome Coating

- Display

- Touch Screen Interface

- Yarn Tension Control

- Electronic

- Safety Feature

- Emergency Stop & Overload Protection

Warping Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 10 Days

About Warping Machine

Warping Machine/Latex/Spendex

FAQs:

Q: What is a Warping Machine?

A: Warping Machine is a type of textile machinery that is used in the preparation of yarns for the weaving process. It is used to wind multiple yarns onto a beam in a parallel and organized manner, creating a "warp" that can be used for weaving.

Q: How does a Warping Machine work?

A: Warping Machine works by winding the yarns onto a beam in a specific pattern, usually by using a creel to hold the yarn cones. The machine may also use various tension devices to ensure the proper tension and organization of the yarns during the winding process.

Q: What is warping machine in technology?

A: Warping Machine in technology is a type of textile machinery used in the preparation of yarns for the weaving process. It is used to wind multiple yarns onto a beam in a parallel and organized manner, creating a warp that can be used for weaving. The machine typically uses a creel to hold the yarn cones and various tension devices to ensure proper tension and organization of the yarns during the winding process.

Cutting-Edge Automation Meets High Capacity

This warping machine integrates advanced automatic systems and PLC controls to deliver consistent, high-speed operation for large textile production lines. With a 7.5 kW power rating and support for a width of up to 2800 mm, it is ideal for heavy-duty, continuous operation, improving productivity and workflow efficiency within the textile sector.

User-Friendly and Reliable Operation

The machine boasts a touch screen display and electronic yarn tension control for precise adjustments, while automatic lubrication reduces manual maintenance. Safety is prioritized through emergency stop and overload protection systems, and a low noise level ensures a more pleasant factory environment, making it a reliable choice for modern textile operations.

FAQs of Warping Machine:

Q: How does the electronic yarn tension control benefit the warping process?

A: The electronic yarn tension control system ensures consistent tension throughout the warping process, minimizing breakages and improving yarn quality. This results in smoother operations and higher-quality finished products.Q: What is the usage procedure for the touch screen interface?

A: The touch screen interface provides an intuitive platform for machine setup and monitoring. Operators can control settings such as speed, tension, and beaming schedules, as well as monitor operational parameters for efficient, error-free production.Q: When is maintenance required for the automatic lubrication system?

A: The automatic lubrication system is designed to function continuously and requires minimal intervention. Regular monitoring of lubricant levels and occasional checks as per the user manual are sufficient to maintain optimal performance.Q: Where can this warping machine be installed?

A: This floor-standing machine is suitable for large textile production facilities, export units, and manufacturing plants across India, requiring a stable power supply (380V, 50/60Hz) and space to accommodate its sizable dimensions.Q: What types of yarns are compatible with this machine?

A: The warping machine efficiently processes cotton, polyester, viscose, and blended yarns, making it highly versatile for various textile manufacturing requirements.Q: How does the heavy-duty beaming device improve productivity?

A: The heavy-duty, automatic beaming device accelerates the process of winding yarn onto beams, increasing throughput and reducing downtime during yarn changes.Q: What are the main benefits for exporters and suppliers using this warping machine?

A: Exporters and suppliers benefit from increased production speeds, consistent yarn quality, enhanced automation, and reliable safety featuresall of which help meet international quality standards and tight delivery schedules.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Needle Loom & Jacquard Machine Category

Computerrized Narrow Fabric Jacquard Loom

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 4001200 Picks Per Minute

Power : 24kW (Depending on Model Width & Heads)

Automatic Grade : Automatic

Size : Customizable (Standard Size Available)

Computerized Jacquard Needle Loom

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : Up to 600 mm weaving width

Power : 3.5 kW 5 kW

Automatic Grade : Automatic

Size : Standard/Customizable

Double Needle Loom

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 150200 m/h

Power : 4 kW

Automatic Grade : Automatic

Size : Standard Industrial

Zipper Belt Needle Loom

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Capacity : 24 pieces/minute

Power : 1.5 kW

Automatic Grade : SemiAutomatic

Size : Standard

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS