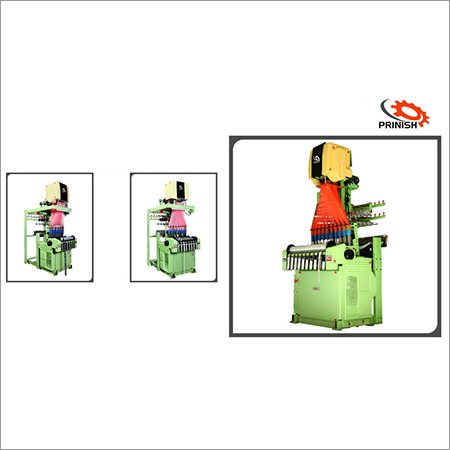

Computerized Jacquard Needle Loom

Computerized Jacquard Needle Loom Specification

- Type

- Computerized Jacquard Needle Loom

- Material

- Heavy-duty Steel, Aluminum Alloys

- Capacity

- Up to 600 mm weaving width

- Printing Speed

- Up to 1500 rpm

- Computerized

- Yes

- Automatic Grade

- Automatic

- Plate Type

- Jacquard Head

- Print Direction

- Multi-directional Weaving

- Color Management

- Multiple Yarn Color Capability

- Control System

- PLC Based Control Panel with Touch Screen

- Working Temperature

- 5C 45C

- Power

- 3.5 kW 5 kW

- Size

- Standard/Customizable

- Width

- 600 mm

- Weight (kg)

- Approx. 1800 kg

- Dimension (L*W*H)

- 3400 mm x 1200 mm x 2200 mm

Computerized Jacquard Needle Loom Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 10 Days

About Computerized Jacquard Needle Loom

Special Features and General Applications

The Computerized Jacquard Needle Loom boasts a harmonized blend of proprietary technology and ingenious engineeringdelivering output up to 500 meters daily. Its expansive 7-inch color touchscreen, automatic lubrication system, and noise-defensive mechanism (<75 dB) facilitate ease and comfort. Use it confidently for producing jacquard ribbons, elastic/non-elastic tapes, and intricate webbings with customizable weaving density and digital pattern storage. Additional features like color yarn management and multi-directional weaving amplify creative potential for both standard and specialized textile projects.

Export Markets, Domestic Reach, and Certifications

Our Computerized Jacquard Needle Looms are shipped globally, with primary markets including Europe, Southeast Asia, the Middle East, and the Americas. Domestic outflow encompasses industrial centers across China. Each shipment is backed by rigorous quality certifications, ensuring compliance and peace of mind for every outlay. Designed for seamless integration into diverse production environments, we guarantee consistent reliability through standardized and customizable models, confidently delivered to satisfy regional and global textile industry needs.

FAQs of Computerized Jacquard Needle Loom:

Q: How does the automatic lubrication system enhance operational efficiency?

A: The automatic lubrication system ensures all moving parts remain optimally lubricated, minimizing maintenance downtime and extending the longevity of the loom for consistent, uninterrupted weaving.Q: What types of yarn can be used with this Jacquard Needle Loom?

A: This loom accommodates cotton, polyester, nylon, and blended yarns, providing flexibility for various fabric compositions in webbing, ribbons, and tape productions.Q: Where can this loom be effectively utilized?

A: The loom is ideal for both specialized and general textile facilities, particularly for manufacturing jacquard ribbons, elastic and non-elastic tapes, and technical webbings.Q: What process is involved in storing and managing patterns?

A: Patterns are easily stored and managed using USB or SD cards, taking advantage of the looms large memory to recall, modify, and implement complex weaving designs on-demand.Q: What safety features are included to protect users during operation?

A: Safety is prioritized with emergency stop controls and overload protection integrated into the loom, reducing risk and enhancing worker security during production runs.Q: When is it best to schedule maintenance for this loom?

A: Regular maintenance is minimal, thanks to the automatic lubrication, but routine inspections are recommended based on usage intensity to ensure optimal performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Needle Loom & Jacquard Machine Category

Computerrized Narrow Fabric Jacquard Loom

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : Other, PLC Controlled with Touchscreen Interface

Dimension (L*W*H) : 2400mm x 1100mm x 1800mm

Capacity : 4001200 Picks Per Minute

Computerized : Yes

Warping Machine

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : Other, PLC Controlled

Dimension (L*W*H) : 3800 x 2800 x 1800 mm

Capacity : 1000 meters/hour

Computerized : Yes

Double Needle Loom

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : Other, PLC Controlled

Dimension (L*W*H) : 5200 mm x 1800 mm x 2400 mm

Capacity : 150200 m/h

Computerized : Yes

Zipper Belt Needle Loom

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : Other, Manual with Mechanical Controls

Dimension (L*W*H) : 1900 x 1200 x 1500 mm

Capacity : 24 pieces/minute

Computerized : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free