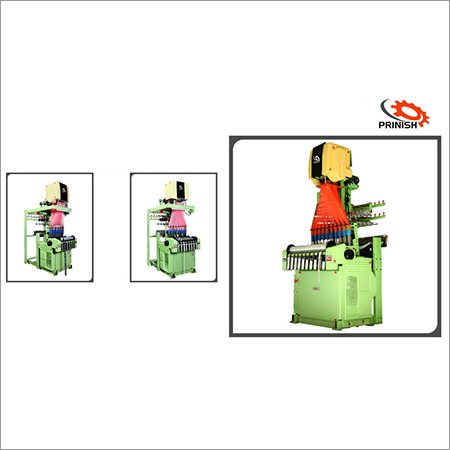

Double Needle Loom

Double Needle Loom Specification

- Type

- Double Needle Loom

- Material

- High-quality Steel and Alloy

- Capacity

- 150-200 m/h

- Printing Speed

- 150-200 m/h

- Computerized

- Yes

- Automatic Grade

- Automatic

- Plate Type

- Flatbed

- Print Direction

- Single/Double Sided

- Control System

- PLC Controlled

- Working Temperature

- 5C - 40C

- Power

- 4 kW

- Size

- Standard Industrial

- Width

- 400 mm - 800 mm

- Weight (kg)

- 1800 kg

- Dimension (L*W*H)

- 5200 mm x 1800 mm x 2400 mm

- Application

- Woven Sack, Jumbo Bag, Geo Textile Tape Weaving

- Warranty Support

- On-site & Online Service

- Take-up Motion

- Automatic Roll Winder

- Yarns Feed

- Automatic

- Noise Level

- < 80 dB

- Lubrication System

- Automatic Centralized Lubrication

- Drive System

- Servo Motor Driven

- Number of Needles

- 2

- Safety Device

- Emergency Stop and Safety Covers

- Power Consumption

- 4-5 kW/h

- Voltage

- 380V/50Hz

- Fabric Denier Range

- 600D - 2000D

Double Needle Loom Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 10 Days

About Double Needle Loom

Double Needle Loom: Applications & Surface Utility

Used across diverse surface applications, the Double Needle Loom is notably utilized in the production of woven sacks, jumbo bags, and precise geo textile tapes. This machine is perfect for automatic weaving on flatbed plates, facilitating both single and double-sided print directions. The application extends to high-denier fabrics in the range of 600D2000D, ensuring performance in industries requiring durable, high-strength textile tapes. It is truly a praiseworthy choice for textile manufacturing environments demanding accuracy and consistency.

Double Needle Loom: Certifications, Samples & Delivery

Our Double Needle Loom is shipped with all relevant certifications to meet stringent industry standards, guaranteeing trustworthy quality. Sample policies support product evaluation before order finalization. Rely on swift transportation logistics with timely shipped goods, ensuring prompt delivery at your facility every time. Our streamlined process ensures you receive delivered equipment in excellent condition, ready for seamless integration into your production line. Experience dependable service and clear communication for a stress-free procurement journey.

FAQs of Double Needle Loom:

Q: How does the Double Needle Loom improve textile production efficiency?

A: The Double Needle Loom automates yarn feeding and roll winding, operates at a high speed of 150200 m/h, and features computerized controls. This streamlines processes and reduces manual intervention, resulting in higher productivity and consistent output.Q: What are the primary applications for this loom in industrial settings?

A: This loom is chiefly used for weaving woven sacks, jumbo bags, and geo textile tapes, catering to industries that require tough, high-denier woven materials and standardized textile outputs.Q: Where is the Double Needle Loom manufactured and supplied from?

A: The loom is manufactured, supplied, and exported from India, catering to domestic and international markets as a reliable solution for textile manufacturers.Q: What type of warranty and support can customers expect?

A: Customers receive comprehensive on-site and online service support for warranty claims, ensuring both rapid technical assistance and sustained operational reliability.Q: What is the process for evaluating samples before placing bulk orders?

A: Sample policies enable customers to request samples for quality evaluation prior to finalizing a bulk purchase, offering reassurance and transparency during procurement.Q: How does the automatic lubrication and safety system benefit users?

A: The centralized automatic lubrication reduces maintenance needs, extending equipment lifespan, while the emergency stop and safety covers enhance operator safety during operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Needle Loom & Jacquard Machine Category

Computerrized Narrow Fabric Jacquard Loom

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : 7001400 kg

Dimension (L*W*H) : 2400mm x 1100mm x 1800mm

Control System : Other, PLC Controlled with Touchscreen Interface

Working Temperature : 5C 40C

Computerized Jacquard Needle Loom

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : Approx. 1800 kg

Dimension (L*W*H) : 3400 mm x 1200 mm x 2200 mm

Control System : Other, PLC Based Control Panel with Touch Screen

Working Temperature : 5C 45C

Warping Machine

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : 3200 kg

Dimension (L*W*H) : 3800 x 2800 x 1800 mm

Control System : Other, PLC Controlled

Working Temperature : 5C 40C

Zipper Belt Needle Loom

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : Approx. 350 kg

Dimension (L*W*H) : 1900 x 1200 x 1500 mm

Control System : Other, Manual with Mechanical Controls

Working Temperature : Normal/Room Temperature

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free