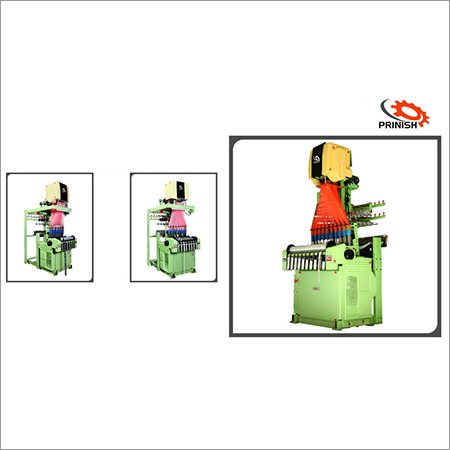

Zipper Belt Needle Loom

Zipper Belt Needle Loom Specification

- Type

- Zipper Belt Needle Loom

- Material

- Stainless Steel, MS (Mild Steel)

- Capacity

- 2-4 pieces/minute

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Plate Type

- Standard

- Print Direction

- Bidirectional

- Control System

- Manual with Mechanical Controls

- Working Temperature

- Normal/Room Temperature

- Power

- 1.5 kW

- Size

- Standard

- Width

- 2 to 6 inch

- Weight (kg)

- Approx. 350 kg

- Dimension (L*W*H)

- 1900 x 1200 x 1500 mm

- Operation

- Heavy Duty Continuous Operation

- Needle Type

- Multi-Needle

- Lubrication

- Automatic or Manual

- Application

- Zipper tape and webbing manufacturing

- Voltage

- 220V/380V

- Drive System

- Belt Driven

- Noise Level

- Low

- Max Width of Tape

- Up to 50 mm

Zipper Belt Needle Loom Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 10 Days

About Zipper Belt Needle Loom

Zipper Belt Needle Loom machine is often used in high-volume production lines to manufacture a wide range of fabric belts and accessories, including backpacks, bags, and other items that require strong, interlocked fabrics. It is often used in conjunction with other textile machinery, such as cutting and finishing machines, to produce finished products that meet exacting quality standards.Robust and Versatile Performance

Engineered for heavy-duty applications, the Zipper Belt Needle Loom is capable of continuous operation with minimal maintenance. Its multi-needle configuration allows for efficient manufacturing of zipper tapes and webbings, making it a valuable asset for textile and garment industries.

Precision Engineering for Quality Output

With a belt-driven mechanism and standard plate type, this machine ensures precise folding, sewing, and cutting. The robust construction using stainless steel and mild steel guarantees consistent operation and long-term reliability.

User-Friendly Controls and Application

Featuring manual and mechanical control systems along with semi-automatic operation, the loom is straightforward to use and requires minimal technical expertise, allowing for easy integration into existing production lines. Its adaptable design caters to various widths and material types.

FAQs of Zipper Belt Needle Loom:

Q: How is the Zipper Belt Needle Loom operated for continuous heavy-duty production?

A: The Zipper Belt Needle Loom uses a belt-driven system and is designed for continuous, heavy-duty operation. Its semi-automatic functionality and multi-needle setup allow operators to manufacture zipper tapes and webbing efficiently, with simple mechanical controls for precision.Q: What materials and widths can this machine handle?

A: This loom can process both stainless steel and mild steel materials. It accommodates tapes and webbings up to 50 mm wide, and its adjustable design allows for various standard sizes and widths between 2 and 6 inches.Q: When should I choose automatic versus manual lubrication?

A: Automatic lubrication is ideal for higher-volume or prolonged use, reducing maintenance intervals and ensuring smoother operation. Manual lubrication is suitable for smaller-scale production or when closer control over the machines upkeep is preferred.Q: Where is the Zipper Belt Needle Loom mainly used?

A: Primarily, this loom is used in textile manufacturing settings, especially those involved in producing zipper tape and diverse webbing products. It is widely utilized by exporters, manufacturers, and suppliers throughout India and beyond.Q: What is the process for setting up and operating the loom?

A: To set up, install the machine on a flat surface and ensure power connectivity to either a 220V or 380V supply. Adjust the needle settings and thread the material through the guides. Operate using the manual mechanical controls while monitoring production and maintaining regular lubrication.Q: How does using this loom benefit my production facility?

A: The Zipper Belt Needle Loom offers low-noise, continuous operation, reliable output (2-4 pieces/minute), and adaptability for various sizes, improving productivity and ensuring robust, accurate manufacturing for zipper tapes and webbing applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Needle Loom & Jacquard Machine Category

Computerrized Narrow Fabric Jacquard Loom

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Width : 30mm 700mm

Control System : Other, PLC Controlled with Touchscreen Interface

Weight (kg) : 7001400 kg

Power : 24kW (Depending on Model Width & Heads)

Computerized Jacquard Needle Loom

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Width : 600 mm

Control System : Other, PLC Based Control Panel with Touch Screen

Weight (kg) : Approx. 1800 kg

Power : 3.5 kW 5 kW

Double Needle Loom

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Width : 400 mm 800 mm

Control System : Other, PLC Controlled

Weight (kg) : 1800 kg

Power : 4 kW

Warping Machine

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Width : Up to 2800 mm

Control System : Other, PLC Controlled

Weight (kg) : 3200 kg

Power : 7.5 kW

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free