Nylon Long Chain Zipper Machinery

Nylon Long Chain Zipper Machinery Specification

- Type

- Nylon Long Chain Zipper Machinery

- Material

- High-strength Alloy Steel and Premium Components

- Capacity

- 80-120 meters/min

- Computerized

- Yes

- Automatic Grade

- Fully Automatic

- Control System

- PLC Control System with Touch Screen Interface

- Working Temperature

- 5C - 45C

- Power

- 4.5 kW

- Size

- Standard Industrial Size

- Width

- 950 mm

- Weight (kg)

- 1350 kg

- Dimension (L*W*H)

- 2850 mm x 950 mm x 1850 mm

- Application

- Continuous production of nylon zipper chains for garment and luggage industries

- Cooling System

- Integrated Cooling Fan

- Noise Level

- <68 dB

- Voltage

- 380V / 50Hz

- Operation Mode

- User-friendly digital interface with multi-language support

- Replacement Parts

- Easy-to-replace components

- Safety System

- Multiple Emergency Stop Buttons & Safety Shields

- Drive Type

- Servo Motor Driven

- Number of Needles

- 4-6 (Customizable)

- Lubrication System

- Automatic Oil Lubrication

Nylon Long Chain Zipper Machinery Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 10 Days

About Nylon Long Chain Zipper Machinery

Established in the year 2003, we are engaged in manufacturing and exporting an exceptional range of Nylon Long Chain Zipper Machinery. These machines are used for designing nylon zippers that used in garments, bags, tents and trolleys. Our Nylon Long Chain Zipper Machinery is made and designed from top quality materials at our state of the art machining facility. We can also customize these machines as per the needs of the clients.

Features:

- Easy to operate

- Compact design

- Energy efficient

Advanced Technology for Efficient Production

Equipped with a PLC control system, touch screen interface, and servo motor, this machine offers precision and speed. The computerized operations minimize manual intervention, enhancing productivity and reducing error rates. Its fully automatic grade ensures seamless operation and reliable output for large-scale manufacturers.

Safety and User-Friendly Operation

Prioritizing operator safety, the machine features multiple emergency stop buttons, safety shields, and a well-ventilated design with an integrated cooling fan. The digital user interface offers multi-language support, making it accessible for diverse production teams. Automatic oil lubrication extends the lifespan of key components while maintaining smooth operation.

FAQs of Nylon Long Chain Zipper Machinery:

Q: How does the Nylon Long Chain Zipper Machinery support efficient zipper chain production?

A: The machine is designed for continuous operation at speeds of 80-120 meters per minute. Its fully automatic, servo-driven mechanism and computerized PLC control system streamline zipper manufacturing, reducing manual labor and downtime.Q: What safety features are integrated into this nylon zipper machinery?

A: Safety is ensured with multiple emergency stop buttons and protective safety shields. These features help prevent accidents during operation, making it suitable for high-volume manufacturing environments.Q: When is maintenance required and how easy is it to replace parts?

A: Routine maintenance is simplified by the automatic oil lubrication system, which keeps components running smoothly. Most replacement parts are easily accessible and designed for quick replacement, minimizing machine downtime.Q: Where can this machine be utilized effectively?

A: This machinery is ideal for zipper production lines within garment and luggage manufacturing industries. Its standard industrial size and robust build make it suitable for factories and large-scale production facilities.Q: What are the benefits of the servo motor drive and integrated cooling system?

A: The servo motor drive delivers precise, consistent motion while maintaining energy efficiency. The integrated cooling fan regulates the operating temperature, ensuring stable performance and extending the machines lifespan.Q: How user-friendly is the operation process?

A: Operation is simplified with a digital touch screen interface that supports multiple languages. The intuitive controls and user-focused design make training and daily use straightforward for operators.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Zipper Machines Category

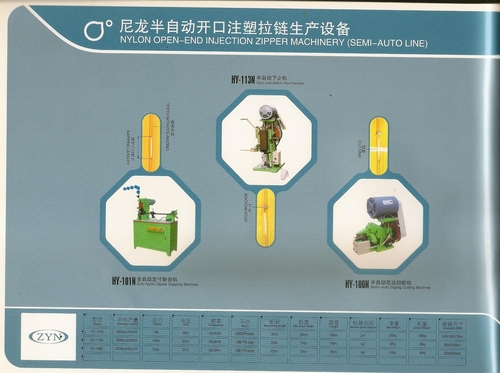

NYLON OPEN END INJECTION MACHINERY

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Computerized : Yes

Power : 7.5 kW

Capacity : Adjustable Up To 240 pcs/hour

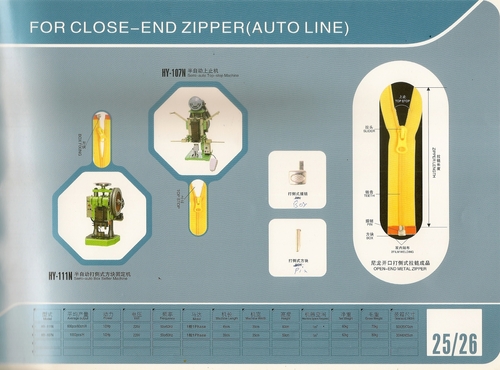

Metal Zipper Machine

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Computerized : Yes

Power : 2.2 kW

Capacity : 8000 Pcs/Hour

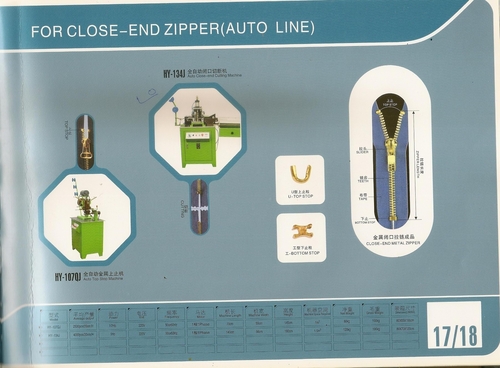

Metal Close end Zipper Machines

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Computerized : Yes

Power : 2.2 kW

Capacity : 8001000 Pieces/Hour

Semi Auto Line OPEN END ZIPPER MACHINERY

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : SemiAutomatic

Computerized : Yes

Power : 2.8 kW

Capacity : 25003000 pcs/hour

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS