zipper top stop machine

zipper top stop machine Specification

- Type

- Zipper Top Stop Machine

- Material

- High-grade steel and aluminum alloy

- Capacity

- 5500-6000 pieces per hour

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Electromechanical control

- Working Temperature

- 5C - 40C

- Power

- 220V/50Hz, 1.5KW

- Size

- Standard

- Width

- 450 mm

- Weight (kg)

- 250 kg

- Dimension (L*W*H)

- 1200mm x 450mm x 1450mm

zipper top stop machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 10 Days

About zipper top stop machine

We have embarked our presence in this industry as a reliable manufacturer and exporter of Zipper Top Stop Machine. These machines can precisely hit double top stops for nylon zipper, thus extensively demanded for designing zipper for bags and plastic packaging covers. We employ advance machines and quality approved materials to manufacture Zipper Top Stop Machine, in accordance with industry set norms and standards. We offer these machines to our esteemed clients at a pocket friendly price.

Features:

- User friendly design

- Sturdy construction

- Easy to install

Efficient Automatic Zipper Top Stop Attachment

This machine streamlines the process of attaching brass or aluminum top stops to zippers automatically. Using electric drive and a pedal-operated start and stop system, it ensures high-speed, accurate placement for nylon, plastic, and metal zippers, meeting industrial demands for stability and consistent quality. Its intuitive electromechanical control system facilitates straightforward operation for manufacturers and suppliers.

User-Friendly and Safe Operation

Designed with operator safety as a priority, this machine includes an emergency stop switch and overload protection to prevent accidents during use. The system operates quietly at less than 65 dB, creating a comfortable work environment. Its semi-automatic functionality reduces manual intervention while maintaining efficiency, and the easy-to-use pedal mechanism enables quick start and stop actions.

FAQs of zipper top stop machine:

Q: How does the zipper top stop machine automate attaching top stops to zippers?

A: The machine uses a dedicated electromechanical control system and pedal-operated startstop mechanism to automatically attach brass or aluminum top stops to zippers. This not only streamlines the production process but also ensures uniform placement and high output rates for various zipper types.Q: What types of zippers and top stops are compatible with this machine?

A: This machine is suitable for nylon, plastic, and metal zippers, and can attach top stops made of brass or aluminum. It offers consistent results regardless of zipper material, making it versatile for a wide range of zipper manufacturing applications.Q: When should I perform maintenance on the zipper top stop machine?

A: The machine is designed for low regular maintenance. Routine checks and basic cleaning should be conducted according to the operating manual to ensure optimal performance and longevity, but intensive maintenance is not frequently required.Q: Where is the optimal operating environment for this machine?

A: For best results, operate the machine indoors within a temperature range of 5C to 40C. Ensure there is proper ventilation and space (minimum machine dimensions are 1200mm x 450mm x 1450mm) to facilitate ease of access and safe operation.Q: What is the process for starting and stopping the machine during production?

A: Operators control the machine using a foot pedal; pressing the pedal starts the process, and releasing it brings the operation to a stop. Additionally, emergency and overload safety features provide enhanced operational control.Q: How does using this machine benefit manufacturers and suppliers?

A: Manufacturers and suppliers benefit from high production efficiency, consistent quality, reduced manual labor, and improved workplace safety. The machines reliability and after-sales service support further enhance productivity and operating confidence.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

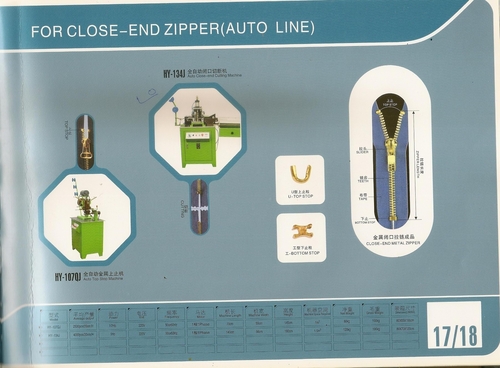

More Products in Zipper Machines Category

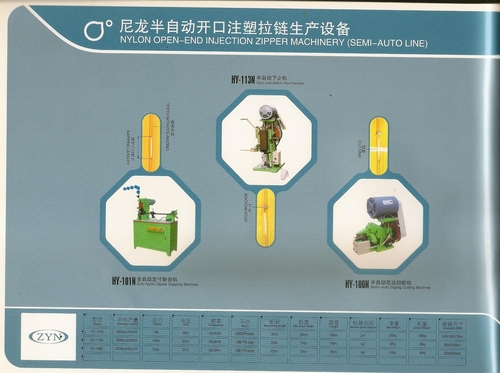

NYLON OPEN END INJECTION MACHINERY

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 3200 mm x 900 mm x 1800 mm

Type : Open End Injection Machinery

Size : Standard Industrial

Working Temperature : Up to 80C

Metal Zipper Machine

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 2200 mm x 800 mm x 1600 mm

Type : Metal Zipper Machine

Size : Standard Industrial

Working Temperature : 5C35C

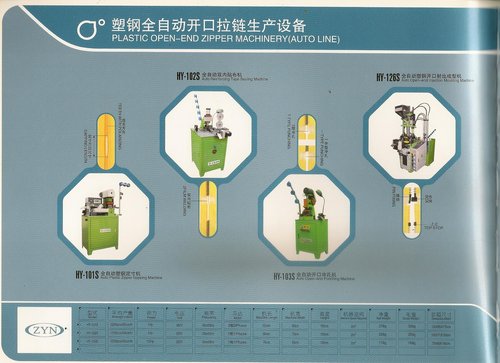

PLASTIC ZIPPER MACHINERY

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 3000 x 1200 x 1800 mm

Type : Plastic Zipper Making Machine

Size : Standard

Working Temperature : 045C

Semi Auto Line OPEN END ZIPPER MACHINERY

Price Range 30000.00 - 300000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Dimension (L*W*H) : 2200 mm x 850 mm x 1900 mm

Type : Semi Auto Line OPEN END ZIPPER MACHINERY

Size : Standard Industrial

Working Temperature : 5C 35C

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS